- Packing - Handling - Logistics

- Packing and Packaging

- Automatic skin-pack machine

- Zappe Packaging Technology GmbH & Co. KG

- Products

- Catalogs

- News & Trends

- Exhibitions

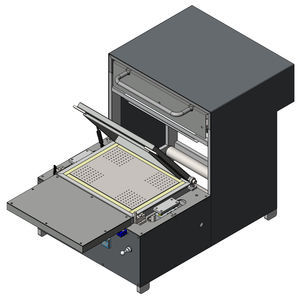

Automatic skin-pack machine SKVAsemi

Add to favorites

Compare this product

Characteristics

- Options

- automatic, semi

Description

The fully automatic skin packaging machine SKVA in the "Pro" variant consists of a loading table with four workstations for loading the skin cartons, an automatic skin station and an automatic longitudinal and transverse cutter for trimming the finished products. The skin machine can be operated by means of a selector switch both in single and continuous cycles, with an integrated vacuum tank being installed for cycle acceleration.

• Low-noise and (almost) maintenance-free, high-performance vacuum pump

• Energy-saving heating with short warm-up time

• Electronic control of heating temperature

• Continuous and 1/10-second setting of the time parameters for reproducible results

• Loading table for 4 workstations, i.e. 4 skinkartons can be loaded and then skined in a clocked manner

• Automatic function sequence after start-up

• Automatic withdrawal of goods after each skin process

• Automatic separation of the pack from the skin film reel after each cycle

• Functional sequence with Programmable Logic Controller

• Machine control by means of a comfortable touch panel

• Longitudinal and transverse cutters for trimming the packaging

• Stencil holder

• Product Recognition

• Cooling blower

• Thermoforming equipment

• Vacuum tank

• Electronic counter

• Level control of the film roll

• Memory module for cross cutters

• Euro Punching Machine

• Air Poster Design

• Automatic cutting support for air cushions

• Automatic return of goods

Other Zappe Packaging Technology GmbH & Co. KG products

Skin Packing Machines

Related Searches

- Packing machine

- Automatic packing machine

- Packing machine for the food industry

- Vacuum packing machine

- Film packing machine

- Bell type packing machine

- Sealer

- Bag packing machine

- Packaging machine for the food industry

- Medical packing machine

- Thermoformer

- Automated thermoforming machine

- Horizontal packing machine

- Semi-automatic packing machine

- Packaging machine for the pharmaceutical industry

- Packaging thermoformer

- Compact packing machine

- Granular packing machine

- Manual packing machine

- Roll-fed thermoformer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.