- Building - Construction

- Construction and Mining Equipment

- Hammer crusher

- ZCJK Intelligent Machinery Wuhan Co. Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

Hammer crusher ZCJKstationarycoalfine

Add to favorites

Compare this product

Characteristics

- Technology

- hammer

- Mobility

- stationary

- Other characteristics

- coal, fine

- Capacity

Min.: 5 t/h

(3.1 lb/s)Max.: 80 t/h

(49 lb/s)- Motor power

Min.: 7.5 kW

(10.2 hp)Max.: 132 kW

(179.47 hp)

Description

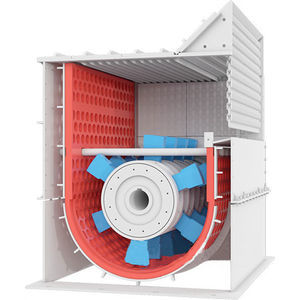

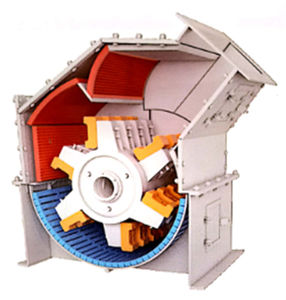

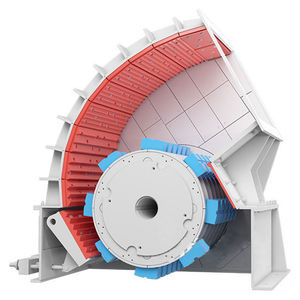

Hammer crusher is mainly used for crushing medium hardness and brittle materials, such as coal, cement, plaster, alum, brick, tile, limestone. Compressive strength of material should not exceed 300 MPa, humidity less than 15%. The apparatus has a simple structure, large crushing ratio, high productivity, uniform product size and other characteristics. It may achieve different expected size according to customer requirements.

The main working part of hammer crusher is rotor with a hammer head composed of a main shaft, a disc, a pin and a hammer. In the lower rotor, with sieve plate. The motor drives the rator rotates at high speed in the crushing cavity, material from the upper feed port into the machine, by the impact of high-speed movement of the hammer, polishing and grinding. Mesh size smaller than the fine material discharged through the sieve, sieve size larger than the coarse crushed material is prevented from continuing in the sieve, finally discharged through the sieve.

Other ZCJK Intelligent Machinery Wuhan Co. Ltd products

Stone Crusher

Related Searches

- Crushing plant

- Stationary crushing and screening plant

- Impact crushing and screening plant

- Jaw crushing and screening plant

- Secondary crushing and screening plant

- Compact crushing and screening plant

- Fine crushing and screening plant

- Sand production crushing plant

- Coal crushing plant

- Hammer crusher

- Hydraulic jaw crusher

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.