- Building - Construction

- Construction and Mining Equipment

- Jaw crusher

- ZCJK Intelligent Machinery Wuhan Co. Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

Jaw crusher PE seriesstationary

Add to favorites

Compare this product

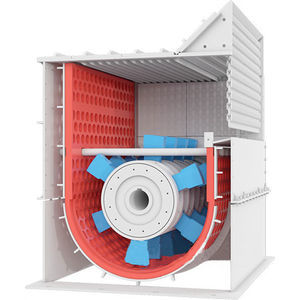

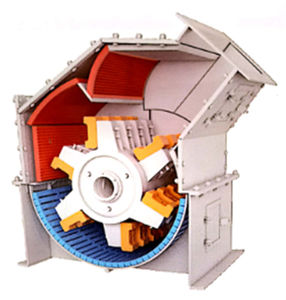

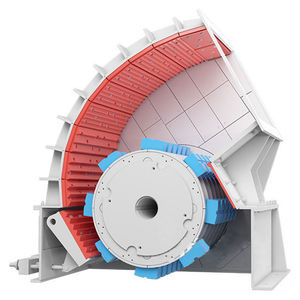

Characteristics

- Technology

- jaw

- Mobility

- stationary

- Capacity

Min.: 1 t/h

(0.6 lb/s)Max.: 110 t/h

(67.4 lb/s)- Motor power

5.5 kW, 7.5 kW, 15 kW, 30 kW, 45 kW

(7.48 hp, 10.2 hp, 20.39 hp, 40.79 hp, 61.18 hp)

Description

PE Jaw crushers are coarse and medium crush and wideh used in the material which compressive strength below 320 MPa. Have the features of large crushing ratio , product size uniformity , solid structure , stable work , easy maintenance, low operating costs. The crusher has been widely in mining, metakkurgy, chemical, building materials, roads, railways, water conservation and other industries.

Performance characteristics

1 - Large and reliable adjusting range of discharge outlet meets various requirements

2 - Safe and reliable lubrication system, easily changed spare parts and easy matainance

3 - Lage crushing ratio and Uniform discharge particle size

4 - Simple structure and low operation cost

5 - Low noise and little dust pollution

Working principle

The motor drives the belt abd the belt wheel to move the movable jaw up and down through an eccentric shaft. When the movable jaw rises, the Angle between the elbow plate and the movable jaw becomes larger, thus driving the movable jaw plate towards the fixed jaw plate. At the same time, the materials is crushed or split to achieve the purpose of crushing. When the jaw goes down, the angle between the elbow plate and the jaw decreases. Under the action of the bar and spring, the jaw plate leaves the fixed jaw plate. At this time the crushed material is discharged from mouth of crushing chamber. With the continuous rotation of the motor, the crushing motor jaw makes periodic motion to crush and discharge materials, realizing mass production.

Other ZCJK Intelligent Machinery Wuhan Co. Ltd products

Stone Crusher

Related Searches

- Crushing plant

- Stationary crushing and screening plant

- Impact crushing and screening plant

- Jaw crushing and screening plant

- Secondary crushing and screening plant

- Compact crushing and screening plant

- Fine crushing and screening plant

- Sand production crushing plant

- Coal crushing plant

- Hammer crusher

- Hydraulic jaw crusher

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.