- Metrology - Laboratory

- Metrology and Test Equipment

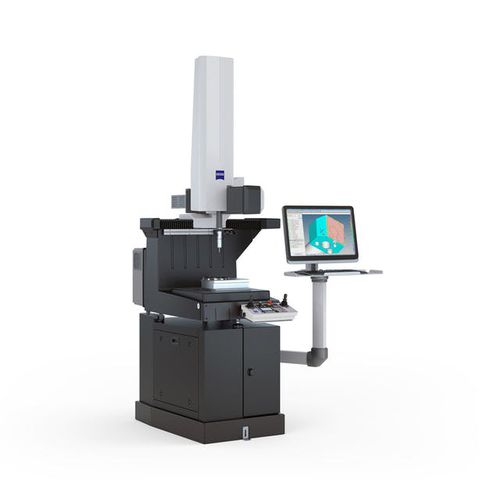

- Bridge coordinate measuring machine

- ZEISS Métrologie et Microscopie Industrielle

Bridge coordinate measuring machine ZEISS DuraMax workshopfor quality controlmulti-sensor

Add to favorites

Compare this product

Characteristics

- Structure

- bridge

- Applications

- workshop, for quality control

- Probe type

- multi-sensor

- Other characteristics

- high-precision, compact

- X travel

500 mm

(19.69 in)- Y travel

500 mm

(19.69 in)- Z travel

500 mm

(19.69 in)

Description

Quality assurance is demanding and CMM requirements are high – especially in the production environment. ZEISS DuraMax combines robustness, precision and efficiency, making it the perfect choice for at-line measurement directly in your production hall. ZEISS DuraMax is not deterred by harsh environmental conditions and withstands even high temperatures. In conjunction with the ZEIS VAST XXT-Sensor it enables fast single-point measurements as well as scanning of contours and free-form surfaces, making fixed gauges superfluous.

Efficiency

Optimal measurement volume/ footprint ratio

Space-saving design for a small footprint

Generous and easily accessible measuring volume

Loading from three sides and from above

No compressed air required

Speed

Reduced operating times and fast measurements

Fast scanning with ZEISS VAST XXT

Single-point measurements with ZEISS VAST probing

ZEISS Duplex System for increased throughput

Four-axis measurement with rotary table

Precision

Precise results even in harsh environments

Dust and moisture protection

IP54 rated ShopFloor base

Thermal stability due to glass ceramic scales

Linear drive nut and ball bearing guiding system with covered guiding in all axes

Passive vibration damping as standard

ZEISS DuraMax HTG offers the widest temperature range with the highest temperature gradient and can be operated both at the production site and in automation systems. This provides more flexibility as you can perform your measurement tasks with even more resistance to environmental influences.

VIDEO

Catalogs

ZEISS DuraMax

6 Pages

Other ZEISS Métrologie et Microscopie Industrielle products

Coordinate Measuring Machines (CMM)

Related Searches

- Carl Zeiss measuring system

- Optical measuring machine

- Automatic measuring machine

- Measurement scanning system

- 3D scanning system

- High-precision measuring machine

- Measuring system for industrial applications

- Carl Zeiss parts measuring system

- Control measuring machine

- Carl Zeiss coordinate measuring machine

- Video measuring machine

- Inspection scanning system

- High-speed scanning system

- High-precision scanning system

- Compact scanning system

- Dimensional measuring machine

- Carl Zeiss 3D measuring system

- Multi-sensor coordinate measuring machine

- Carl Zeiss bridge coordinate measuring machine

- High-speed measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.