- Robotics - Automation - Industrial IT

- Industrial Computing

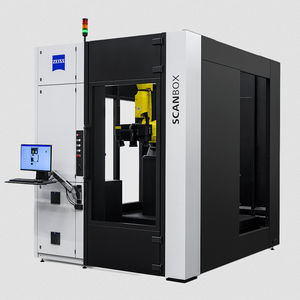

- ZEISS Métrologie et Microscopie Industrielle

Digitizer ZEISS ABIS III

Add to favorites

Compare this product

Description

The newly developed ZEISS ABIS III sensor combines high-speed inspection with a reliable detection of all relevant surface defects such as dents, bulges, sink marks, ripples, neckings, cracks and now also scratches and pressure marks. The system inspects both moving and stationary parts reproducibly and highly precise during live production and within the cycle time. Moreover, it is not only suited for in-line but also for at-line use in the production environment.

The patented Multi-Color-Light technology allows for detecting even the smallest defects. After only a few seconds, a digital inspection report will be issued. This way, functions such as a Q-stop and digital quality details such as defect visualizations for scheduled rework are always available. They provide the basis for closed loop circuits and the precondition for implementing the Smart Process Control. Designed and developed in Germany to fulfill the highest quality standards, ZEISS ABIS III is the ideal solution for both modern press shops and future-oriented body shops.

Surface Inspection

The conventional surface inspection, e.g., treating the surface with grindstones, takes a lot of time and depends on the relevant user. This subjective inspection may cause disagreements between customer and supplier and consequently complaints, claims or costly sorting or reworking tasks. With the use of the sensor ZEISS ABIS III and the fast defect detection rate of up 20 Hz, manual and subjective quality assurance processes become redundant. The resource-efficient system continuously and automatically provides the database required for dedicated rework, quick surface analyses and efficient process optimizations.

VIDEO

Catalogs

No catalogs are available for this product.

See all of ZEISS Métrologie et Microscopie Industrielle‘s catalogsOther ZEISS Métrologie et Microscopie Industrielle products

3D Scanning

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.