- Metrology - Laboratory

- Metrology and Test Equipment

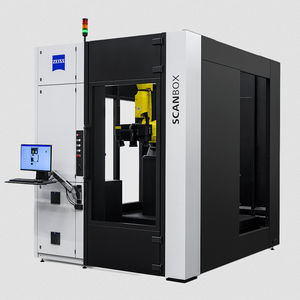

- 3D scanner

- ZEISS Métrologie et Microscopie Industrielle

3D scanner ZEISS ATOS 5for quality controlmeasurementhigh-precision

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3D

- Applications

- measurement, for quality control

- Other characteristics

- high-precision

- Measuring distance

530 mm, 880 mm

(20.9 in, 34.6 in)

Description

Due to its advanced camera technology, a strong light source, and powerful software, ATOS 5 achieves a new level of performance, especially when measuring shiny and dark surfaces, fine structures, and edges. The technology accelerates the total measuring time while providing precise 3D measuring data at the same time.

Fast measurements

Variable system

Comprehensive process and quality control

ATOS 5 accelerates production processes

ATOS 5 delivers full-field 3D scans: of tools and molds, plastic and metal parts. The data enables comprehensive process and quality control by making errors and defects visible.

Speed up your measurements

Full-field 3D scans

ATOS 5 accelerates the inspection process. The system achieves short exposure times, even on shiny and dark surfaces. Thanks to its large measuring areas, the optical 3D scanner becomes even faster, allowing you to obtain 3D data quickly and thus increase productivity.

Robust precision

Developed for industrial use

ATOS 5 meets the high metrological requirements of industrial users. The system provides absolute and traceable measurement data even under harsh conditions. With its stereo camera setup, ATOS 5 includes a built-in, sensor-controlled reliability monitor for measurements. Our integrated software provides you with ongoing feedback on calibration status, the measurement accuracy, environmental changes, and part movements.

Versatile all-rounder

Growing with your needs

Choose ATOS 5 to combine flexibility with precision. Whether on the shop floor or in a measuring room, manual or automated, the system handles complex inspection tasks.

Catalogs

Other ZEISS Métrologie et Microscopie Industrielle products

3D Scanning

Related Searches

- Carl Zeiss measuring system

- Optical measuring machine

- Automatic measuring machine

- Measurement scanning system

- 3D scanning system

- High-precision measuring machine

- Measuring system for industrial applications

- Carl Zeiss parts measuring system

- Control measuring machine

- Carl Zeiss coordinate measuring machine

- Video measuring machine

- Inspection scanning system

- High-speed scanning system

- High-precision scanning system

- Compact scanning system

- Dimensional measuring machine

- Carl Zeiss 3D measuring system

- Multi-sensor coordinate measuring machine

- Carl Zeiss bridge coordinate measuring machine

- High-speed measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.