- Metrology - Laboratory

- Metrology and Test Equipment

- 3D measuring system

- ZEISS Métrologie et Microscopie Industrielle

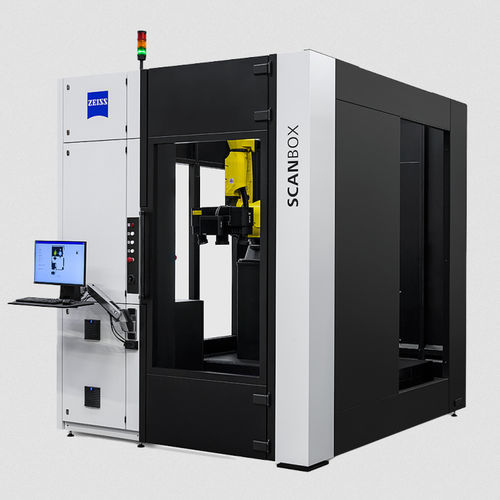

3D measuring machine ZEISS ScanBox 5 RCautomatedparts

Add to favorites

Compare this product

Characteristics

- Technology

- 3D

- Operating mode

- automated

- Measured material

- parts

Description

ZEISS ScanBox Series 5 RC (Remote Control) is an optical measuring machine with a motorized sliding door. With a robot or a customized loading system, you automatically load parts such as airfoils, attached parts or tools into ZEISS ScanBox Series 5 RC and place them on the rotation table module. As the user does not have to place the individual parts, the time required for quality assurance is significantly shorter than before.

High throughput and high repeatability

Precise measuring procedures and optimal comparability

Maximum machine utilization and optimized processes

Production-related quality assurance and serial monitoring

The autonomous operation increases machine utilization, accelerates measuring cycles and allows you to deploy your staff more efficiently. ZEISS ScanBox Series 5 RC is available in two model variants and has been specially designed for applications that require a high degree of integration and throughput. Due to its small footprint, the system can be smoothly integrated into every production line.

Precise measuring procedures and optimal comparability

Quality assurance during series production is all about monitoring production processes, reducing scrap and minimizing the need for rework. For this application, the ZEISS ScanBox Series 5 RC optical measuring machine is the ideal solution. Directly compare the actual coordinates of serial parts that were created entirely in 3D with an ATOS 5 sensor with the CAD model or with specifications from a measurement plan. Create inspection reports directly at your production facilities and export them to statistical process-control systems.

Catalogs

No catalogs are available for this product.

See all of ZEISS Métrologie et Microscopie Industrielle‘s catalogsOther ZEISS Métrologie et Microscopie Industrielle products

3D Scanning

Related Searches

- Carl Zeiss measuring system

- Optical measuring machine

- Automatic measuring machine

- Measurement scanning system

- 3D scanning system

- High-precision measuring machine

- Measuring system for industrial applications

- Carl Zeiss parts measuring system

- Control measuring machine

- Carl Zeiss coordinate measuring machine

- Video measuring machine

- Inspection scanning system

- High-speed scanning system

- High-precision scanning system

- Compact scanning system

- Dimensional measuring machine

- Carl Zeiss 3D measuring system

- Multi-sensor coordinate measuring machine

- Carl Zeiss bridge coordinate measuring machine

- High-speed measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.