- Metrology - Laboratory

- Metrology and Test Equipment

- 3D measuring system

- ZEISS Métrologie et Microscopie Industrielle

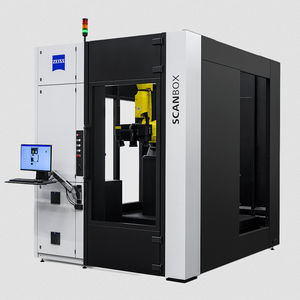

3D measuring machine ATOS ScanBox 8automatedpartscontrol

Add to favorites

Compare this product

Characteristics

- Technology

- 3D

- Operating mode

- automated

- Measured material

- parts

- Applications

- control

- Other characteristics

- high-precision

Description

This 3D measuring machine is designed for something big: With ATOS ScanBox Series 8 you can digitize complete vehicles at high speed, both from the outside and the inside. The modular measuring cell has established itself among OEMs as a complete solution for analyses in master jig and cubing, the inspection of finished vehicles, and for quality assurance in car body manufacturing. Take advantage of the wide range of possibilities of ATOS ScanBox Series 8: Virtually merge measurements of multiple parts and use the powerful ZEISS INSPECT software for linear evaluation of detailed information on gap and flush.

Automated scanning in duplex mode

Measurement of body-in-white, hang-on parts, marine engines and tools

Analysis in master jig & cubing

Automated scanning in duplex mode

Synchronous use of two robots in one measuring cell

Two 8-axis kinematics allow for full-field measurement of particularly large assemblies. The duplex mode ensures synchronous, coordinated use of two robots in the measuring cell. In this process, a joint data set of measurements is created, as the double robot mode takes place in a shared coordinate system. Depending on your needs, the two robots of ATOS ScanBox Series 8 can also be used for independent measurement on two different parts.

Accelerated measurement and inspection of body-in-white

Reference frame for ATOS ScanBox Series 8

The new reference frame for ATOS ScanBox Series 8 makes production control in series even more efficient. The flexible system is ready to go without any preparation time. You can significantly increase your throughputs. Inspect more than 1000 measurement features, s

VIDEO

Catalogs

No catalogs are available for this product.

See all of ZEISS Métrologie et Microscopie Industrielle‘s catalogsOther ZEISS Métrologie et Microscopie Industrielle products

3D Scanning

Related Searches

- Carl Zeiss measuring system

- Optical measuring machine

- Automatic measuring machine

- Measurement scanning system

- 3D scanning system

- High-precision measuring machine

- Measuring system for industrial applications

- Carl Zeiss parts measuring system

- Control measuring machine

- Carl Zeiss coordinate measuring machine

- Video measuring machine

- Inspection scanning system

- High-speed scanning system

- High-precision scanning system

- Compact scanning system

- Dimensional measuring machine

- Carl Zeiss 3D measuring system

- Multi-sensor coordinate measuring machine

- Carl Zeiss bridge coordinate measuring machine

- High-speed measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.