- Industrial machines and equipment

- Printing, Marking and Engraving

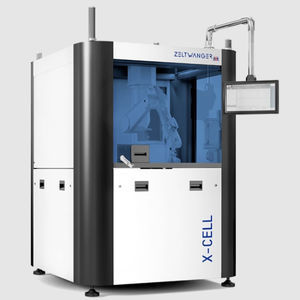

- Laser marking machine

- Zeltwanger Thermomanagement GmbH & Co. K

Laser marking machine X-LOAD cobotfor integrationautomatedrobotic

Add to favorites

Compare this product

Characteristics

- Technique

- laser

- Configuration

- for integration

- Other characteristics

- automated, robotic

Description

Many production processes today are almost fully automated – apart from components, which still have to be manually inserted into the processing stations. Automated loading saves time and money and production can continue even after shift-end.

The X-LOAD cobot is our automated system platform for realizing round-the-clock production..

In the medical technology sector, for instance, manual laser workstations for labeling surgical instruments, implants (UDI labeling) or other components with a large number of different types and parts are the standard.

The use of our X-LOAD cobot loading platform, combined with a collaborating robot, reduces the production costs per workpiece as your components can be processed around the clock without requiring any staff.

The system platform starts paying for itself already with low unit volumes and/or a large number of different parts from batches with 15 units.

Orders can be managed in drawers.

The processing station can be automatically or manually loaded and continued to be used as an individual station.

The operator can operate several systems at the same time.

A protective housing is not required thanks to the collaborating robot.

No knowledge of robotics is required for setting up new components.

It is extremely simple to set up the loading platform, which makes it possible to respond quickly to production and market changes.

Our system platform can be operated together with any manually loaded machine.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Zeltwanger Thermomanagement GmbH & Co. K‘s catalogsOther Zeltwanger Thermomanagement GmbH & Co. K products

Automation platforms

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.