- Industrial machines and equipment

- Welding and Assembly

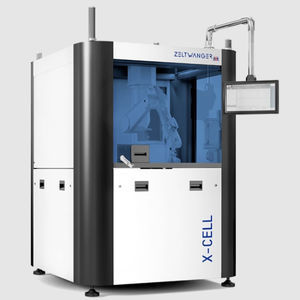

- Laser welding machine

- Zeltwanger Thermomanagement GmbH & Co. K

Laser welding machine X-WELDroboticcompactintegrated

Add to favorites

Compare this product

Characteristics

- Technique

- laser

- Operational mode

- robotic

- Other characteristics

- compact, integrated, rotary

- Power

10 W

Description

Want to work comfortably at a manual welding laser despite having limited space available? With the X-WELD, this is no problem!

Thanks to its ergonomic design, manual laser welding processes can be carried out fatigue-free over an extended period.

ERGONOMICS AND MULTIFUNCTIONALITY COMBINED

The X-WELD is a compact, ergonomic manual welding laser that has been specially designed for long and complex component geometries. The front of the spacious work area is fitted with flaps made from a multi-layer, passive protective material, meaning there is no need for a bulky door opening. Thanks to the compact design, the X-WELD can fit into any space in any setting.

Laser area separated by design

Operation of the platform is safe for the environment. The operator is protected against laser radiation. A large laser safety window below the microscope provides a direct view into the work area and protects the user from reflected laser beams.

Process flexibility

Various metals (steel, aluminum, copper, gold, titanium, etc.) can be welded. It is also possible to work both with and without supplementary material.

Connection of different laser sources

Different laser sources can be integrated in order to meet the high demands of the various industries. Laser sources from Trumpf or IPG are used as standard. Tests can be conducted on request to determine the suitability of other laser sources.

Additional retrofit options

Various components (such as a rotary axis, T-grooved plate, or work area monitoring unit) can be retrofitted as required.

Catalogs

No catalogs are available for this product.

See all of Zeltwanger Thermomanagement GmbH & Co. K‘s catalogsOther Zeltwanger Thermomanagement GmbH & Co. K products

Automation platforms

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.