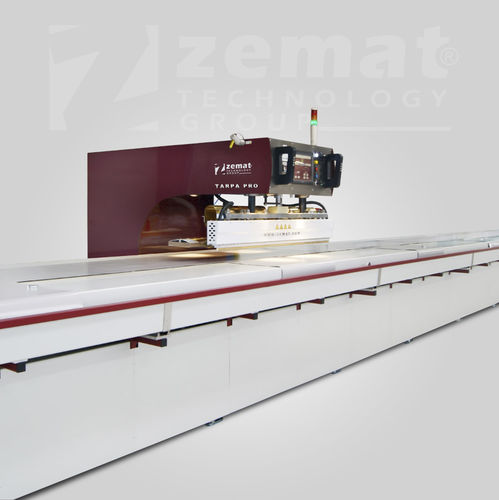

TARPA PRO HF Welder heat sealer is designed specifically for production of large format tensile structures, membranes, tarpaulin, tents, oil booms, truck covers, swimming pool liners & covers, airline hangars, large billboards, fast doors, side curtains, etc. Machine can be equipped with special impulse electrode for welding non-HF weldable fabrics made of PE and PP, as well as FlexEL ’soft’ multilayer welding electrode and curved HF electrodes for sealing round window profiles made of clear PVC and any other shapes requiring precision welding.

TARPA PRO model is equipped with special high precision ball bearing linear motion gear, controlled by frequency inverter and glide-on railing to achieve a perfect continuous straight line seam. Optional vacuum work table with the length up to 50 meters and laser guides allow handling of large format materials and precision weld positioning for fast production setup.

FEATURES:

Frequency inverter rail driven HF welding head

Linear ball bearing drive for high precision continuous welds

High efficiency HF weld cycles with 6/10/15/20 or 25kW output power

Sealing efficiency from 1kW: 40cm2 for standard PVC materials

Work table length up to 50m with optional vacuum system

Universal usage for PVC, PU, TPU, reinforced technical textiles

Easy material positioning with back trough and laser guides

1500mm electrode length (1700mm for Tarpa PRO25)

PE, PP weldability with optional impulse electrode

10" touch screen color HMI panel with expanded functionality

SafeDOWN™ electrode motion safety system

WCS™ Weld Check System

ATS™ Autotuning and ultrafast ARC limiter (solid-state antiflash)

Built in VPN client and VNC server