- Industrial machines and equipment

- Mixing and Dosing

- Plowshare mixer

- Zeppelin Silos & Systems

- Products

- Catalogs

- News & Trends

- Exhibitions

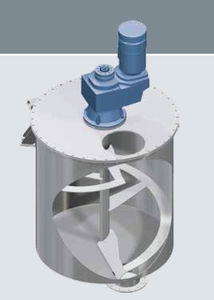

Plowshare mixer HMF seriesbatchsolidhorizontal

Add to favorites

Compare this product

Characteristics

- Technology

- plowshare

- Batch/continuous

- batch

- Product type

- solid

- Configuration

- horizontal

- Other characteristics

- stainless steel

- Applications

- for the food industry

- Capacity

Max.: 4,500 l

(1,188.77 gal)Min.: 500 l

(132.09 gal)

Description

Applications

The horizontal mixer HMF is designed for mixing tasks from free-flowing and hard to handle dry materials to liquid and paste-like masses with varying bulk densities. Due to various designs gentle mixing process – with low energy input – but also intensive mixing processes can be realized.

The HMF can be used in every field of the food industry where highest quality and reliability is essential such as baby food, baking mixtures, cereals, spices, instant products, cakes/desserts, dietary supplements, soups/sauces, chocolate and sugar masses.

Design characteristics

The mixer is composed of a horizontal mixing trough with mixing tools mounted to the drive shaft. This shaft is driven by a side-mounted gear motor via a drive coupling. The top of the mixer is designed with studs that are used for filling or aspiration of the mixing trough. The pneumatically operated, wide opening outlet on the bottom of the mixing trough is equipped with a cleaning valve. A large, manually-operated lid which is assisted by gas pressure supports enables an easy cleaning of the mixing trough. The mixing tools can be arranged as slanted mixing paddles or as the proven plough-shovel arrangement as appropriate for the corresponding mixing task. The inner mixing area as well as the mixing tool mounting have no bolted connections and all surfaces are polished (max. Ra = 0.8 µm).

Catalogs

No catalogs are available for this product.

See all of Zeppelin Silos & Systems‘s catalogsRelated Searches

- Dynamic homogenizer

- Batch homogenizer

- Liquid agitator

- Homogenizer for the food industry

- Solid blender

- Vertical agitator

- Stainless steel agitator

- In-line mixer

- Solid/liquid homogenizer

- Horizontal blender

- Construction agitator

- Paddle blender

- High-speed homogenizer

- Automatic homogenizer

- Concrete kneader

- Ribbon blender

- Rotor agitator

- Conical screw blender

- Hopper loader

- Conical blender

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.