- Industrial machines and equipment

- Mixing and Dosing

- Paddle mixer

- Zeppelin Silos & Systems

- Products

- Catalogs

- News & Trends

- Exhibitions

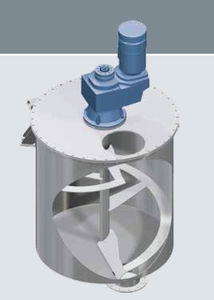

Paddle mixer SHEARDOS VM seriesbatchsolid/liquidvertical

Add to favorites

Compare this product

Characteristics

- Technology

- paddle

- Batch/continuous

- batch

- Product type

- solid/liquid

- Configuration

- vertical

- Other characteristics

- automatic, clean-in-place (CIP)

Description

Applications

Beside simple agitating and mixing of liquid components shear flow mixers can be used for intensive mixing and smooth homogenizing of dry materials with liquids. Thereby, the raw materials’ characteristics are not destroyed and can develop in the mixture. In baking operations, e.g. flour is mixed with water, oil, yeast and cultures to liquid sponge and sourdough. After less than two minutes a homogenous product is generated which can be perfectly processed. For a better hydration a dough yield of TA 200 is recommendable. For example, dough for muffins, wafers and pancakes can be produced with the ShearDos. This mixing task can be realized batchwise or continuously in combination with other systems.

Design characteristics

Compact, stable and low-vibration stainless-steel construction. Cylindrical mixing hopper with stators on the hopper wall. The

vertical mixing cylinder has a cone shaped bottom in which the product is discharged. A rotor rotates in the hopper which is driven from above by a geared motor. The mixing process is based on the rotor-stator principle.

Cylindrical mixing hopper (stator) in stainless steel (inside ground, outside glass pearl blasted)

A hinged door in the hopper wall allows easy inspection and cleaning

60° discharge cone with discharge and connection stud to determine the filling height by a pressure transmitter

Additional design features of the ShearDos

Drive on top, angle and height adjustable

The removable lid allows cleaning from the top

Additional design features for the WIP variant (washing in place)

Removable filling stud

Cleaning heads (target jet cleaner) can manually used from outside

Catalogs

No catalogs are available for this product.

See all of Zeppelin Silos & Systems‘s catalogsRelated Searches

- Dynamic homogenizer

- Batch homogenizer

- Liquid agitator

- Homogenizer for the food industry

- Solid blender

- Vertical agitator

- Stainless steel agitator

- In-line mixer

- Solid/liquid homogenizer

- Horizontal blender

- Construction agitator

- Paddle blender

- High-speed homogenizer

- Automatic homogenizer

- Concrete kneader

- Ribbon blender

- Rotor agitator

- Conical screw blender

- Hopper loader

- Conical blender

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.