- Industrial machines and equipment

- Mixing and Dosing

- Batch mixer

- Zeppelin Silos & Systems

- Products

- Catalogs

- News & Trends

- Exhibitions

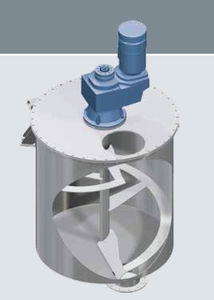

Batch mixer KroMixfor liquidsverticalhigh-speed

Add to favorites

Compare this product

Characteristics

- Batch/continuous

- batch

- Product type

- for liquids

- Configuration

- vertical

- Other characteristics

- high-speed

- Applications

- dough

Description

Consistently high-quality dough guaranteed, with mixing times reduced by up to 50%: The new KroMix system makes it possible.

High-speed meets batch mixing

With DymoMix you can mix dry and liquid ingredients before they are dosed into the bowl of the Kronos digital. For the mixing process, the flour and water are both atomized so that individual flour particles fall through a mist, absorbing water molecules as they do so. The centrifugal effect of the atomization introduces energy, with the result that a gluten network starts to develop right from when the water molecules are absorbed. The mixed dough can be transferring to the kneading system and kneaded straight afterwards, with no need to mix the ingredients any further and no more flour dust produced during kneading.

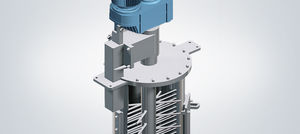

Perfect dough at the push of a button

The Kronos digital system has been fitted with sensors and an intelligent, self-regulating controller to automatically stop the kneading process at just the right moment. The kneading phase automatically adapts to fluctuating raw material and ambient parameters, and ends at the ideal point,

with consistently good-quality doughs produced every time, thanks to defined parameters. The forecasting of factors such as viscoelastic dough properties makes it possible for processing to be adapted to specific dough characteristics. All measured data are recorded for quality control, and conclusions regarding production conditions and raw materials can also be drawn from these data. Documented measured data include energy consumption, ambient temperature, dough temperature, as well as the firmness and viscosity of the dough.

Catalogs

ZEPPELIN_FOL_KROMix_

2 Pages

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Liquid agitator

- Homogenizer for the food industry

- Solid blender

- Vertical agitator

- Stainless steel agitator

- In-line mixer

- Solid/liquid homogenizer

- Horizontal blender

- Paddle blender

- Construction agitator

- High-speed homogenizer

- Automatic homogenizer

- Concrete kneader

- Ribbon blender

- Rotor agitator

- Conical screw blender

- Hopper loader

- Conical blender

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.