- Metrology - Laboratory

- Analytical Instrumentation

- Alcohol analyzer

- ZEUTEC Opto-Elektronik GmbH

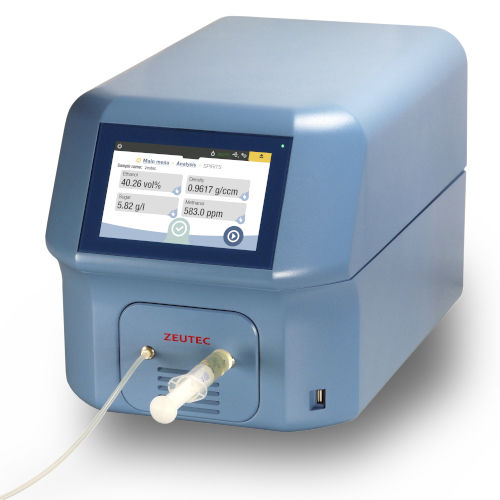

Distillation analyzer SpectraAlyzer SPIRITSalcohollaboratoryprocess

Add to favorites

Compare this product

Characteristics

- Measured entity

- alcohol

- Application domain

- process, laboratory, industrial

- Measured value

- stability, density, distillation

Description

The SpectraAlyzer SPIRITS is the simple solution for routine analysis of the basic quality parameters in industrial spirits production and (crafts) distilling.

In spirits production, the SpectraAlyzer SPIRITS performs the important quality tests such as alcohol content, density and total sugars within a few seconds. Thus, the distilling process and downstream processing can be closely monitored by analysing samples from any stage of the production line – without sample preparation and the use of reagents or other consumables.

The immediately available, precise quality information enables better process control and thus a higher product yield with consistently good product quality. Whether you want to determine the state of the distillation/rectification process, dilution, bottling process or oversee individual production batches – the SpectraAlyzer SPIRITS provides you instantly with the information you need.

Whether high or low alcohol content – the analyser system shows excellent linearity up to 98 % vol alcohol content. Even contained or added sugar does not affect the accurate readings.

The robust design of the analyser allows flexible installation both in the laboratory and directly in the production process, where temperature fluctuations, humidity, dust and shock have no effect on the accuracy and long-term stability of the measurements. Additional accessories e.g. a peristaltic pump and robotic autosamplers can be added to enhance the sample throughput to > 60 samples per hour.

Thanks to the integrated web server, the analytical values, batch protocols and trend charts are immediately available in the company’s own network – and, if desired

VIDEO

Catalogs

No catalogs are available for this product.

See all of ZEUTEC Opto-Elektronik GmbH‘s catalogsRelated Searches

- Concentration analyser

- Monitoring analyser

- Liquids analyser

- Automated analyzer

- Dust analyzer

- Spectrometer

- Process analyser

- Real-time analyser

- Compact analyser

- Laboratory analyser

- Calibration analyser

- Sampling analyser

- Lab spectrometer

- Analyser for the food industry

- Quality control analyser

- Moisture analyser

- Compact spectrometer

- Modular analyser

- Rugged analyser

- Food analyzer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.