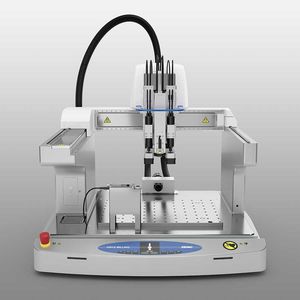

PCB rework station ONYX 49hot airautomaticfor SMD

Add to favorites

Compare this product

Characteristics

- Type

- hot air

- Operational mode

- automatic

- Applications

- for SMD, for PCB

Description

With the ONXY 49, very large and heavy PCBs can be processed with a high level of user-friendliness. The robust construction and the fully automatic motorized axes guarantee highest precision and repeatability.

• PCB size up to 800 mm x 630 mm.

• PCB thickness up to 10 mm.

• Processing of components from 01005 up to 110 mm x 110 mm.

Main features

• 2000 W multi-function hot gas heating head:

- Soldering of components.

- Removing of components.

- Contactless and automatic removal of residual solder.

• All axes are motorized with closed loop motion control.

• Manual movement via integrated handwheels for fast and precise positioning of the hot gas head.

• Automatic and total process control.

• Eight thermocouple ports for process temperature control.

• Large board handling for boards up to 800 mm x 630 mm.

• Flexible board carrier for easy handling of irregularly shaped boards without additional fixtures.

• Adjustable bottom preheaters with a performance of up to 12’000 W including integrated board cooling.

• 3 different controlled cooling systems to observe the temperature profile with the highest precision.

• Automatic closed-loop force control of the Z-axis for automated pick and place, fluxing and removal processes in order to protect sensitive parts.

• High-precision closed-loop gas flow control from 8 to 80 l/min.

• MFOV system for high-resolution inspection of components up to 70 mm x 70 mm (optional 110 mm x 110 mm) with high-resolution images.

• Automatic contactless site cleaning to remove residual solder with a motorized X / Y / Z system.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.