- Hydraulics - Pneumatics

- Pipe, Tube and Fitting

- Hydraulic pipe

- ZHANGJIAGANG ACREE INTL GROUP CO., LTD.

- Products

- Catalogs

- News & Trends

- Exhibitions

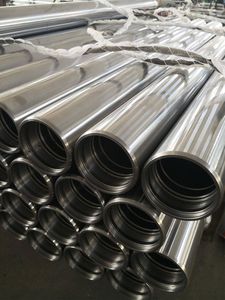

Hydraulic tube stainless steelcarbon steelseamless

Add to favorites

Compare this product

Characteristics

- Use

- hydraulic

- Material

- stainless steel, carbon steel

- Other characteristics

- seamless, solderless

Description

As honed tubes are the most important material of manufacturing hydraulic cylinders.

We manufacture the honed tubes using our factory’s “Suitable To Hone” Steel Cold Drawn Seamless Tubes (CDS tubes).

Hydraulic tubes are cold drawn tubes with the internal surface SRB finished or Honed. The Skived and Roller burnished process is a complex process that is increasing the roughness qualities of the surface. The skiving knives pass first scraping the inside layer of metal. Burnishing rollers are passing afterwards cold working the tube and creating an internal mirror surface finish. Honing is an abrasive machining process that produces a precision surface on a metal workpiece. The process consists of scrubbing an abrasive stone against it along with a controlled path. Honing is primarily used to improve the geometric form of a surface and the surface texture.

Production standards : Our raw material of hot rolled pipes are mainly from famous big mills such as Baosteel, TPCO, Valin, Angang etc, we process cold drawn then honing process or Skiving & Roller Burnishing process. Meanwhile, the tube is usually manufactured according to norms as ASTM A513, DIN 2391, DIN 1630, DIN 1629, EN 10216-2, A 519, on customer’s request.

Carbon steel grades as below:

• SAE 1020

• SAE 1026

• SAE1030/1035

• E355, E255, E215, E235

• ST52.3, St35, ST 52.4, St 37.4

Stainless steel Honed tube can be supplied in grades as below:

• TP 304 / 304L

• TP316 / 316L

• TP 316Ti

Other steel grades of hone tube /honed pipe are available on customer’s request.

Technical Properties.

• Diameter Tolerance for ID: ISO H8 (EN ISO 286-2). We can provide special tolerance at a premium price.

Other ZHANGJIAGANG ACREE INTL GROUP CO., LTD. products

Cold Drawn Seamless Mechanical Tubes

Related Searches

- Piping

- Tube

- Smooth piping

- Steel tube

- Flexible tube

- Stainless steel tube

- Corrosion-resistant pipe

- Pneumatic tube

- Welded piping

- Hydraulic tube

- Air tube

- Seamless piping

- Smooth tube

- Welded tube

- Abrasion-resistant tube

- High pressure pipe

- Hydrocarbon pipe

- Tube for the food industry

- Tube for automotive applications

- Seamless tube

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.