- Materials - Tools - Components

- Semi-finished products

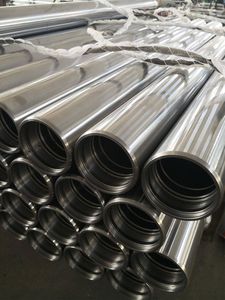

- Steel rod

- ZHANGJIAGANG ACREE INTL GROUP CO., LTD.

- Products

- Catalogs

- News & Trends

- Exhibitions

Steel rod quenchedchrome

Add to favorites

Compare this product

Characteristics

- Shape

- rod

- Other characteristics

- quenched, chrome

- Diameter

Max.: 200 mm

(7.874 in)Min.: 16 mm

(0.63 in)- Mechanical resistance

5,600 bar, 5,800 bar, 6,500 bar, 7,100 bar

(81,221.1 psi, 84,121.9 psi, 94,274.5 psi, 102,976.8 psi)

Description

Induction hardening is a form of heat treatment in which the chrome plated steel bar is heated by induction heating and then quenched. This heat treatment is increasing the hardness and brittleness of the chrome plated bars.

Induction Hardened Chrome plated steel bars are used as piston rods for hydraulic cylinders in applications operating in standard and demanding conditions.

Our customers use Induction Hardened Chrome plated steel bars to produce pneumatic cylinders that work at pressures higher than 200 bars.

Applications for standard conditions are defined as applications working in a non-particular corrosive environment. Applications for demanding conditions are used in heavy duty and corrosive environment.

We recommend these chrome plated steel bars made from C45E+IH steel for most standard piston rods.

Diameter Tolerance Standard is ISO-f7. We can provide special tolerance at a premium price.

Residual Magnetism Standard is Max. 50 Gauss. We can provide special magnetism at premium price.

Roundness – max ½ from the diameter tolerance.

Surface roughness: Ra0.2μm ~ Ra0.4μm (8 Ra – 16 Ra)

Surface Hardness Chrome Layer hardness is a minimum of 850 HV 0,1. Steel-grade C45E IH surface hardness is from 50~60HRC.

Straightness for ∅20[mm] is minimum 20[µm].

Corrosion Resistance is given by the salt spray test results. These tests are following the ISO 9227 and ISO 10289 standards. The results of these tests are giving the rating of our products.

Induction Hardened Depth, Hardness Depth 1.6-3.5 mm

Other ZHANGJIAGANG ACREE INTL GROUP CO., LTD. products

Cold Drawn Seamless Mechanical Tubes

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.