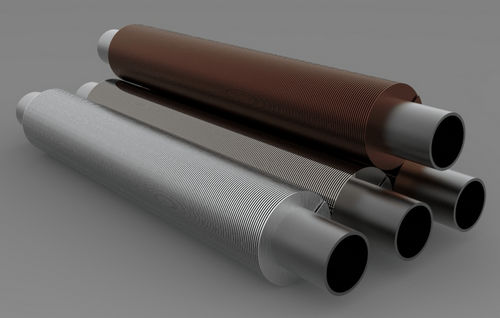

We manufacture Welded and Applied Fin Tubes in large-scale with excellent ability to manufacture high-specification tube from 15.88mm to 219mm Diameter.

Typical examples of applications where finned tubes are used include the following:

• A wide variety of economizers and waste heat recovery units to utilize heat from boiler flue gas, gas turbine exhaust, incinerators, etc.

• Glycol dehydration units

• Fired heaters, such as LNG vaporizers, air pre-heaters, oil heaters, etc.

• Asphalt tank heaters

• Air coolers, such as compressor jacket water and lube oil coolers

• Lumber drying kilns, and similar applications

• Livestock enclosure and greenhouse heaters

Finned tubes are used in applications involving the transfer of heat from a hot fluid to a colder fluid through a tube wall. The rate at which such heat transfer can occur depends on three factors: (1) the temperature difference between the two fluids; (2) the heat transfer coefficient between each of the fluids and the tube wall; and (3) the surface area to which each fluid is exposed. In the case of a bare (unfinned) tubes, where the outside surface area is not significantly greater than the inside surface area, the fluid with the lowest heat transfer coefficient will dictate the overall heat transfer rate. When the heat transfer coefficient of the fluid inside the tube is several times larger than that of fluid outside the tube (for example steam inside and oil outside), the overall heat transfer rate can be greatly improved by increasing the outside surface of the tube.