- Hydraulics - Pneumatics

- Valve

- Gate valve

- Zhejiang Gute Pneumatic Machinery Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

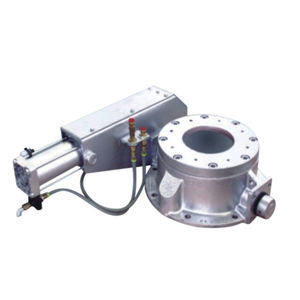

Gate valve Z644TC pneumaticfor controlfor air

Add to favorites

Compare this product

Characteristics

- Type

- gate

- Operation

- pneumatic

- Function

- for control

- Media

- for air

- Body

- waterproof

- Applications

- chemical, for oil industry applications, for powders, abrasive, flange, plate , plate

- Fluid specification

- for powders

- Associated function

- discharge

- Other characteristics

- compact, high-performance, high-temperature, pressure seal, waterproof, wear-resistant, high-performance, energy-saving, for flue gas

- DN

Max.: 300 mm

(11.811 in)Min.: 50 mm

(1.969 in)- Pressure

1 MPa

- Temperature

450 °C

(842 °F)

Description

Ceramics Double Plate Gate Valve adopts double valve plate, and the sealing pair adopts high-grade toughening structural ceramics manufactured by nanotechnology. Its practical performance is much higher than that of ordinary structural ceramics, cemented carbide and other wear-resistant materials. It solves the problem that the sealing surface is easy to be eroded due to material erosion, and its service life is not high. Its service life is 5-10 times longer than that of ordinary material valves, which brings reason to users. The desired use effect and economic benefits are conducive to equipment detection and operation adjustment, thus significantly improving the overall operation safety and economy.

Z644TC Ceramics Double Plate Gate Valve Because of the particularity of the structure design, it can be used in high temperature situations, which is an important characteristic different from other similar valves.

Scope of application

It is suitable for opening and closing of gas and slag in dry ash system of power plant, as well as for opening and closing of abrasive, corrosive, powder and flue gas in mines, steel, papermaking and petrochemical industries.

Key Points of Installation and Use

1. Read this instruction carefully before installation, and check valve type, size and technical parameters.

2. It is strictly forbidden to Weld flanges after installing valves. The valve installation distance reserved from the pipeline shall be appropriate, and gaskets shall be added on both sides of the flange.

3. The center of the two pipelines and the center of the valve diameter should be coaxial, the flange surface should be flat,and the flange surface should

Other Zhejiang Gute Pneumatic Machinery Co., Ltd products

Industrial Valve Series

Related Searches

- Valve

- Hand valve

- Control valve

- Stainless steel valve

- Ball valve

- Pneumatic valve

- Flap valve

- Non-return valve

- Electric valve

- Biogas valve

- Valve with handwheel

- Butterfly valve

- Piston actuator valve

- Wedge gate valve

- Valve for the chemical industry

- Valve for industrial applications

- Metal non-return valve

- Radial diaphragm valve

- Compact valve

- Fluid check valve

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.