- Hydraulics - Pneumatics

- Valve

- Knife gate valve

- Zhejiang Gute Pneumatic Machinery Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

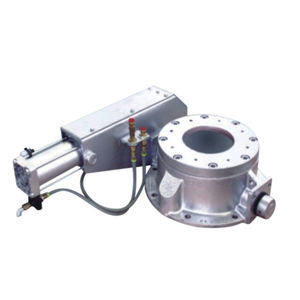

Knife gate valve HZ644HC series pneumaticdoublesmall

Add to favorites

Compare this product

Characteristics

- Type

- knife gate

- Operation

- pneumatic

- Body

- double, small, metal, carbide

- Applications

- for the chemical industry, plate

- Associated function

- service

- Other characteristics

- high-performance, high-performance, pneumatic piston

- DN

Min.: 40 mm

(1.575 in)Max.: 300 mm

(11.811 in)- Pressure

1 MPa

- Temperature

150 °C, 450 °C

(302 °F, 842 °F)

Description

The valve plate on one side adopts original hole design, small start-up load and no plug phenomenon in the valve chamber. On the other side, the valve plate is sealed with carbide on one side, which has strong wear resistance, good sealing performance and long service life.

Working principle

When the air source enters from the upper intake port, the cylinder rod drives the valve plate to move downward and the valve closes. When the air source enters from the lower intake port, the cylinder rod drives the valve plate to move upward and the valve opens. Spring is loaded between the valve plate and the sealing ring, and the spring force always makes the valve plate press towards the sealing ring, and allows the valve plate to move vertically up and down. This helps to compensate for the thermal expansion and contraction of the valve parts, overcomes the influence of any change in back pressure on the sealing and prevents the particle medium from entering the two sealing surfaces. During the opening and closing process, the valve plate can rotate automatically, causing grinding between the sealing surfaces. Because of the eccentricity of the valve body to the passage, eddy current will occur when discharging materials. The material eddy will clean the valve chamber by itself. All these characteristics make the valves have extraordinary service life and provide a reliable guarantee for the safe operation of your system.

Description of Model Compilation Method

HZ Valve Type Code: "HZ" Represents Reciprocating Sliding Gate Valve

6 drive form code: "6" means pneumatic

4 Connection form code: "4" means flange connection

4 Drive Form Code: "4" Represents Parallel Double Sluice

Other Zhejiang Gute Pneumatic Machinery Co., Ltd products

Industrial Valve Series

Related Searches

- Valve

- Hand valve

- Control valve

- Stainless steel valve

- Ball valve

- Pneumatic valve

- Flap valve

- Non-return valve

- Electric valve

- Biogas valve

- Valve with handwheel

- Butterfly valve

- Piston actuator valve

- Wedge gate valve

- Valve for the chemical industry

- Valve for industrial applications

- Metal non-return valve

- Radial diaphragm valve

- Compact valve

- Fluid check valve

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.