- Hydraulics - Pneumatics

- Valve

- Diaphragm valve

- Zhejiang Gute Pneumatic Machinery Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

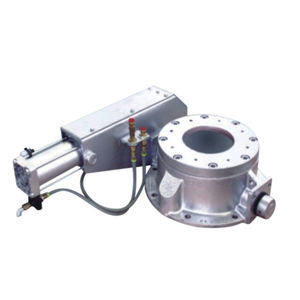

Diaphragm valve GTS series electricpilotfor compressed air

Add to favorites

Compare this product

Characteristics

- Type

- diaphragm

- Operation

- electric

- Function

- pilot

- Media

- for compressed air

- Body

- IP65

- Associated function

- exhaust, outlet

- Other characteristics

- pulse, electromagnetic

- DN

80 mm, 100 mm

(3.15 in, 3.937 in)- Pressure

Max.: 0.6 MPa

Min.: 0.2 MPa

- Temperature

Max.: 55 °C

(131 °F)Min.: -25 °C

(-13 °F)

Description

Through the pilot dividing into one action, the exhaust passage I on the pilot part 1 is connected with the passage II on the cover 2. The compressed air of the upper chamber III of the diaphragm 3 is discharged instantaneously from the passage II on the cover 2 and the exhaust passage I on the pilot part 1. At the same time, the diaphragm 3 moves upward due to the pressure difference between the upper and lower compressed air, so that the passage IV, the exhaust passage V, the exhaust passage VI on the shell 6 are connected with the passage II The passage_on the buffer ring 5 is connected with the cavity_on the upper part of piston 7. The compressed air of the cavity_is discharged through the passage V and_. The piston 7 moves upward rapidly under the pressure difference between the compressed air at the upper and lower ends. Finally, the compressed air in the seven packs (sub-chambers) is ejected from the outlet of the valve to achieve the purpose of ash removal.

Through the action of the pilot part 1, compressed air enters the chamber III through channels I and II. The diaphragm moves downward due to the difference of compressed air pressure between the upper and lower diaphragms. The connection between the six passages IV and the exhaust passage V of the shell is separated. The compressed air in the air bag (air dividing box) enters the upper chamber VII of the piston through passage IX. The piston moves downward due to the action of gravity, and the gas is sealed. The exhaust port of the bag (dividing box).

Other Zhejiang Gute Pneumatic Machinery Co., Ltd products

Industrial Valve Series

Related Searches

- Valve

- Hand valve

- Control valve

- Stainless steel valve

- Ball valve

- Pneumatic valve

- Flap valve

- Non-return valve

- Electric valve

- Biogas valve

- Valve with handwheel

- Butterfly valve

- Piston actuator valve

- Wedge gate valve

- Valve for the chemical industry

- Valve for industrial applications

- Metal non-return valve

- Radial diaphragm valve

- Compact valve

- Fluid check valve

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.