- Industrial machines and equipment

- Heat Exchanger and Refrigeration

- Falling film evaporator

- Zhejiang Sunny Machinery Technology Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

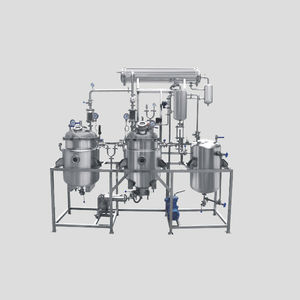

Vacuum evaporator falling filmprocesslow temperature

Add to favorites

Compare this product

Characteristics

- Type

- vacuum, falling film

- Laboratory/process

- process

- Other characteristics

- low temperature

Description

Widely used in pharmaceutical, food, chemical, light industry and other industries, water or organic solvent solution evaporation concentration, and can be widely used in the above industry waste liquid treatment. Especially suitable for heat-sensitive materials, the equipment operates continuously under vacuum and low temperature conditions, with high evaporation capacity, energy saving and consumption reduction, low operating costs, and can ensure the invariance of materials in the evaporation process. The equipment from single-effect to five-effect, production capacity from 1 ton to 10 tons, customers according to material characteristics and production modeling.

Main Features

The principle of film falling evaporator, the liquid from up parts flow to down parts by pipe, the liquid can be distributed uniformly, and it flow from up parts to down parts by gravity and vacuum, it is heated by medium steam during operation, then it will became into steam and liquid, the steam and liquid will be separated in the chamber, the steam will be cooled by condenser ( single effect ) or used for heating steam, at last the liquid will be discharged from the chamber.

1. The principle of film falling evaporator, the liquid from up parts flow to down parts in pipe, the liquid can be distributed uniformly, and it flow from up parts to down parts by gravity and vacuum, it will be sticky during evaporation, and you can get the concentrated liquid at the bottom , the falling film evaporator can evaporate the high density and viscosity(scope from 0.05-0.45ns/m2) material

2. The solution flows like film in the single type evaporator, so the heat transfer coefficient is high

Other Zhejiang Sunny Machinery Technology Co., Ltd. products

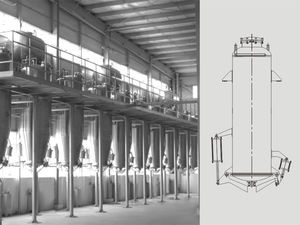

Herbal Extraction Equipment

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.