- Industrial machines and equipment

- Heat Exchanger and Refrigeration

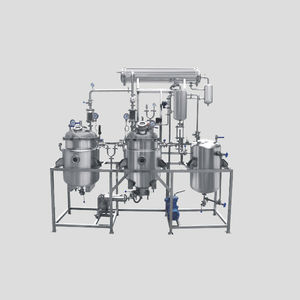

- Thermal evaporator

- Zhejiang Sunny Machinery Technology Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Thermal evaporator forced circulationprocesslow temperature

Add to favorites

Compare this product

Characteristics

- Type

- thermal, forced circulation

- Laboratory/process

- process

- Other characteristics

- low temperature

Description

Forced Circulating Evaporator

Forced circulation evaporator is suitable for scaling, crystal, thermal sensitivity (low temperature), high density, high viscosity raw material, and the evaporation water insoluble solids such as chemical, food, pharmaceutical, environmental protection engineering, waste water evaporation recycling industry.

Working Principle

Forced circulation evaporator rely on external force -- circulating pump

The circulation speed can be 1.5-3.5 meters / seconds.the heat efficiency and production capacity is big, the raw material solvent from down parts to up parts by circulation pump . It flows along the pipe to the heating chamber, then the steam and liquid will be separated at the chamber, the steam will go out from up parts, the liquid will flow at the bottom of the chamber, it will be pumped by circulation pump again, it is again pumped to heating pipe, the heating chamber has horizontal and vertical structure, the liquid flow speed is controlled by pump.according to different circulation liquid inlet and outlet of separating chamber, it can divides to normal circulation evaporator and forced circulation evaporator, the inlet port of circulation liquid above the outlet port is called normal circulation, oppositely, it is forced circulation.

Main features

1. The structure of whole system design is reasonable and beautiful, stable operation, high efficiency and energy saving, low steam consumption.

2. Concentration ratio, forced circulation type, so that the viscosity liquid can be easily flow and evaporated. And it is evaporated during short time.

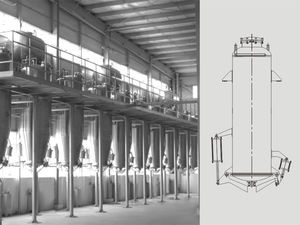

Other Zhejiang Sunny Machinery Technology Co., Ltd. products

Herbal Extraction Equipment

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.