- Packing - Handling - Logistics

- Conveying

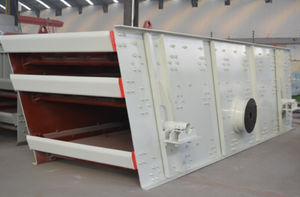

- Belt feeder

- Zhengzhou Dingsheng Engineering Technology Co., Ltd.

Belt feeder BW series industry

Add to favorites

Compare this product

Characteristics

- Type

- belt

- Product applications

- industry

Description

Raw materials: - All kinds of sand or stone

Max feeding size: - 1200mm

Application: - cement, mining, metallurgy, coal, chemical industry, power industry

Shipping ports: - Shanghai, Qingdao or Tianjin

Delivery: - 15-30 days

DSMAC apron feeder has an integral matching scraper conveyor with built-in drive to handle spillage. This system ensures an economic layout and increased belt conveyor length compared with the conventional system with spillage chute. The feeders are specially designed to minimize maintenance.

DSMAC apron feeder is engineered for heavy-duty operation and for primary or subsequent application stages. These custom-built machines are designed to suit individual requirements of capacity, size and material handled.

BW Apron Feeder Features

Impact loads are absorbed by pans of rolled alloy/ cast alloy/ manganese steel material depending on application and are similar to heavy-duty track-type undercarriage shoes.

Pans are bolted to forged link chains supported on heavy-duty lifetime lubricated rollers. High strength pans resist abrasion and withstand heavy impact loads.

Short pitch and precision-machined chain provides noise-free discharge of material with negligible impact on receiver.

Chain and roller flanges maintain rigid alignment of pans in relation to skirt.

Catalogs

No catalogs are available for this product.

See all of Zhengzhou Dingsheng Engineering Technology Co., Ltd.‘s catalogsOther Zhengzhou Dingsheng Engineering Technology Co., Ltd. products

Feeders & Screens

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.