- Environment - Health - Safety

- Waste Treatment

- Concrete recycling unit

- Zhengzhou Dingsheng Engineering Technology Co., Ltd.

Concrete recycling plant for concretecrushing

Add to favorites

Compare this product

Characteristics

- Applications

- for concrete

- Recycled product

- for concrete

- Functions

- crushing

Description

Recently, a 400tph FIXED CONSTRUCTION WASTE RECYCLING PLANT by Zhengzhou Dingsheng has been installed successfully and completed the final commissioning. The entire production line is basically automated, each stage running stably, the finished product is in good granular shape, and the actual output exceeds designed capacity.

This comprehensive construction waste utilization project covers an area of nearly 80 acres, including 10 fixed construction waste recycling plant and recycled concrete decorative brick production lines. The full set of equipment and technical guidance of former line are provided by Zhengzhou Dingsheng. The local demolition waste will be processed with crushing, screening, light material separation, iron removing and other treatments, finally becoming clean and fine-quality aggregates of various sizes that meet building standards, to be used to make decorative bricks and other regeneration products.

Among the fixed construction waste recycling plant, JC jaw crusher and DPF construction waste crusher take a significant position. JC jaw crusher has the characteristics of high production efficiency and low energy consumption. Compared with ordinary jaw crushers with the same specification, its processing capacity is increased by 20-35%, the energy consumption reduced by 15-20%. The crusher adopts hyperboloid jaw plate which abraded less, and the service life can be extended by 3-4 times. In addition, the outlet is hydraulically adjusted with a large adjustment range, easily controlling the discharge specifications.

Catalogs

No catalogs are available for this product.

See all of Zhengzhou Dingsheng Engineering Technology Co., Ltd.‘s catalogsOther Zhengzhou Dingsheng Engineering Technology Co., Ltd. products

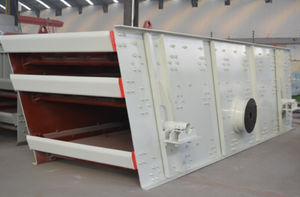

Feeders & Screens

Related Searches

- Crushing plant

- Stationary crushing and screening plant

- Mobile crushing and screening plant

- Impact crushing and screening plant

- Jaw crushing and screening plant

- Recycling plant

- Primary crushing and screening plant

- Secondary crushing and screening plant

- Compact crushing and screening plant

- Crawler crushing and screening plant

- Cone crushing and screening plant

- Fine crushing and screening plant

- Tertiary crushing and screening plant

- Coal crushing plant

- Crushing recycling line

- Roller crusher

- Hammer crusher

- Metal recycling line

- VSI crusher

- Hydraulic cone crusher

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.