- Machine-tools

- Cutting Tool

- Tool holder cutting tool

- Zhengzhou Halnn Superhard Materials Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

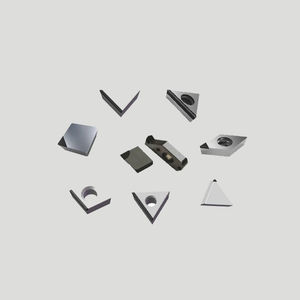

Tool holder cutting tool CBNPCD

Add to favorites

Compare this product

Characteristics

- Other characteristics

- PCD, CBN, tool holder

Description

Index: This is one of the most important market areas of Valin. We can provide a complete set of solutions for the entire rebar roll industry, including turning, grooving, rib cutting, Notching and other tools for rolls of various materials; This is the product catalogue of PCD rib Notching Tools.

LEADING POSITION

We're in the leading position, is the well-known brand in superhard materials and application in China.

SITUABLE SOLUTION

Provide tailored service in superhard material and tools field, devote to offer comprehensive solution to global customers.

MASS STOCK

There is Large stock for standard tools, noted for our quality any service in Chinese high-end market.

BEST COOPERATION

We had prepared the distributorship and service center in the global key markets, is opening to welcome any cooperation for discussion.

Tool Holder for PCD Notching ToolsWith more than 15 years experience, Halnn have researched one by one new materials Grade, New Technology and become the most Famous Cutting Tools Brand in Superhard Cutting Tools Industry. Specific above Casting defects and other problems, Halnn reserached some CBN Inserts and PCD Tools for Machining these High Hardness Rolls.

Mill Rolls are Important Tools and Key Components for Rolling Ferrous Metal Materials. the Cost of Mill Rolls is about 5%~15% of the Rolling Steel Production, Which is Directly Related to the Production Efficiency, Product Quality and Production Cost of the Steel Enterprises. Mill Rolls Can be divided into Casting Rolls, Forging Rolls, Tungsten Carbide Rolls. All of them have High Hardness and Large Allowance, and are difficult To Process.

Other Zhengzhou Halnn Superhard Materials Co., Ltd. products

PCD Tools

Related Searches

- Milling tool

- Solid milling tool

- Drilling tool

- Clamping milling cutter

- Solid drilling tool

- Insert milling tool

- End mill milling tool

- Indexable cutting insert

- General purpose drill bit

- Cutting milling tool

- Face milling tool

- Carbide drilling tool

- Roughing milling tool

- Indexable insert milling tool

- Twist drilling tool

- Diamond milling tool

- Turning tool

- High-precision milling tool

- Insert turning tool

- High-speed milling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.