- Materials - Tools - Components

- Semi-finished products

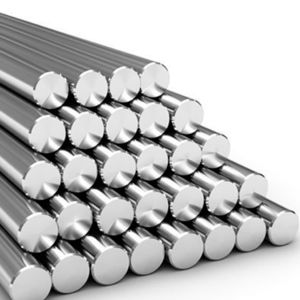

- Aluminum rod

- Zhu Xia Metal Products Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Billet aluminum

Add to favorites

Compare this product

Characteristics

- Shape

- for billets

- Diameter

Min.: 166 mm

(6.54 in)Max.: 1,320 mm

(51.97 in)

Description

7050 Aluminum Casting Billet Xl for Structural Parts

7050 Casting Billet

Homogenization

Diameter Available: 166、220、380、396、448、462、566、582、915、1060、1220、1320 (mm)

Standard: GB/T3190

DESCRIPTION

Casting is a simple, inexpensive and versatile way of forming aluminum into a wide array of products. Aluminum casting billet xl has a wide application range, such items as power transmissions and car engines and the cap atop the Washington Monument were all produced through the aluminum casting process. Most castings, especially large aluminum casting billet xl products, are usually made in sand molds.

Aluminum casting billet xl products process:

The goal of the casting process is to produce aluminum billets xl that meet the requirements. To produce these aluminum casting billets xl, the process includes melting, casting, billet sawing, aluminum billet homogenization, cooling, washing, aluminum billets into the warehouse.

* Remarks: Specific requirement of alloy, temper or specification can be discussed at your request.

Other Zhu Xia Metal Products Co., Ltd. products

Aluminum bar

Related Searches

- Aluminum

- Aluminum alloy

- Aluminum coil

- Aluminum sheet

- Aluminum plate

- Aluminum rod

- Aluminum for aerospace applications

- Aluminum alloy for aerospace applications

- Aluminum alloy plate

- Aluminum alloy sheet

- Square aluminum

- Aluminum alloy sheet metal

- Cold-rolled aluminum

- Aluminum for the automotive industry

- Aluminum alloy for the automotive industry

- Aluminum alloy tube

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.