- Industrial machines and equipment

- Welding and Assembly

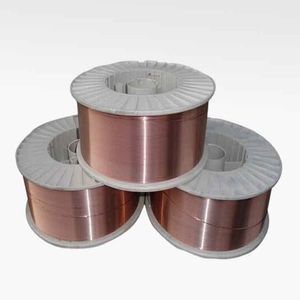

- Flux core welding wire

- Zibo QILU Welding Industry Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Flux core welding wire MG49-1arcgas

Add to favorites

Compare this product

Characteristics

- Type

- flux core

- Technique

- gas, arc

Description

Gas shielded welding wire is divided into two types: solid wire and flux cored wire. In China, solid-core welding wire is mainly used at present, but flux-cored wire is rapidly spreading and has a broad application prospect.

Special welding wire for gas shielded arc welding. According to different manufacturing methods, it is also divided into two types: solid wire and flux cored wire. In China, solid-core welding wire is mainly used at present, but flux-cored wire is rapidly spreading and has a broad application prospect. In Japan, the amount of solid wire is still greater than that of flux-cored wire, but the type of flux-cored wire is more, used for carbon steel, low-alloy high-strength steel, low-temperature steel, heat-resistant steel and stainless steel. Various kinds of welding wires, and various flux-cored welding wires suitable for surfacing. According to the welding method and the shielding gas, it can be divided into TIG welding wire, MIG welding wire and mag welding wire. The TIG welding wire is matched with pure Ar as a shielding gas, and the wire composition is close to the weld composition. MIG welding wire is matched with Ar+2%O2 or Ar+5% CO2 shielding gas, mainly used for welding high alloy steel such as stainless steel. MAG welding wire can be combined with Ar plus 5% or more of CO2 or Ar plus 2% or more of O2 shielding gas, or 100% CO2 as shielding gas. The latter type of shielding gas is low in cost and is widely used for welding carbon steel, low alloy steel and stainless steel, and can also be used for surfacing welding.

Other Zibo QILU Welding Industry Co., Ltd. products

Products

Related Searches

- Welding electrode

- Arc welding electrode

- Steel welding electrode

- Soldering wire

- Arc welding wire

- Carbon steel welding electrode

- Surfacing welding electrode

- Copper soldering wire

- Stainless steel welding electrode

- Coated welding electrode

- Flux core soldering wire

- Heat-resistant welding electrode

- Process welding electrode

- Steel welding wire

- Cast iron welding electrode

- Gas welding wire

- Aluminum welding wire

- Resistance welding wire

- Aluminum alloy welding wire

- Carbon steel welding wire

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.