- Environment - Health - Safety

- Waste Treatment

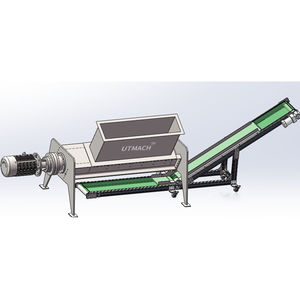

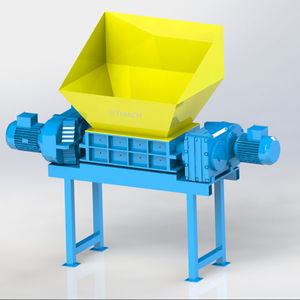

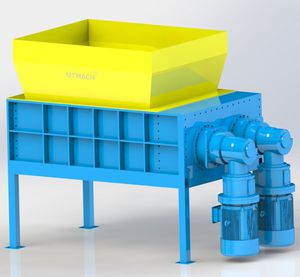

- Double-shaft shredder

- Zibo United Tech Machinery Co., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Double-shaft shredder D seriesfor woodfor cardboardmetal

Add to favorites

Compare this product

Characteristics

- Number of shafts

- double-shaft

- Application

- for wood, for cardboard, metal, tire, paper, solid & bulk waste, for electronics scrap, fabric

- Other characteristics

- high-torque, heavy-duty

Description

D series Double shaft shredder from United Tech Machinery is designed for a wide array of applications and industries. And particularly well suited to the size reduction of bulky or voluminous materials which could include contamination such as metals or stones. Depending on input material and the following process the shredded material can be used directly or go into the next step of size reduction. It can efficient to increase the bulk density and decrease the transportation cost.

Advantages:

* Motor + the Rotor is drived by the reducer, get the effect of slow speed and high torque shredding.

* Six enclosed sealing bearing protection design, waterproof and dustproof, so the life of bearing can be prolonged.

* The wearing blade can be repaired by the most advanced cutting tool coating and welding technology. The blade can be repeated use, reduce the maintenance costs.

* Separated design to the shredding chamber, the frame can be easily discharged the whole Shaft (Rotor, Blade, Bearing, Sealed system).

* Blade is spiral arrangement, get effective shredding.

* Adopt the Hexagon to the blade inner hole and the main rotor, ensuring the blade stability and get equal force.

* To ensure durability and flexibility, we can offer the different kinds of Blades according to different materials.

Typical applications include:

Plastics — Reclaimed Material, Production Waste

Paper — Documents, Mill Waste

Electronic Scrap — WEEE Directive Materials / E-Waste

Tyres — Car, 4×4, Light Commercial, Truck & OTR

Wood — Pallets, Furniture, Board

Packaging Materials — Cardboard

Metals — Aluminium, Copper, Steel (Drums, Sheet etc), ELV Body Shells

Textiles — Clothing, Carpet

VIDEO

Catalogs

Other Zibo United Tech Machinery Co., Ltd. products

Shredder

Related Searches

- Grinding mill

- Crushing plant

- Solid classifier

- Stationary crushing and screening plant

- Liquids separator

- Waste shredding machine

- Eddy current separator

- Baling press

- Pelletizer

- Horizontal grinding mill

- Mobile crushing and screening plant

- Single-shaft shredding machine

- Vertical grinding mill

- Impact crushing and screening plant

- Primary shredding machine

- Wood shredding machine

- Process classifier

- Jaw crushing and screening plant

- Two-shaft shredder

- Recycling plant

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.