Double-wall plate heat exchanger unit welded plategas/gasgas/liquid

Add to favorites

Compare this product

Characteristics

- Type

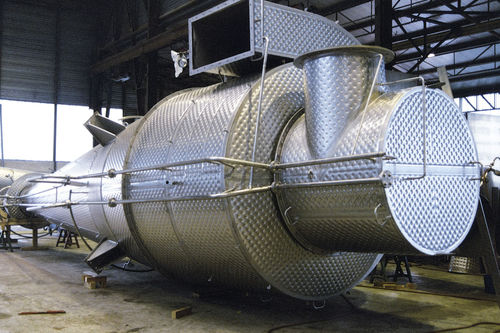

- double-wall plate, welded plate

- Fluid

- gas/gas, gas/liquid, liquid/liquid

- Operating pressure

60 bar

(870.23 psi)- Temperature

Min.: -200 °C

(-328 °F)Max.: 400 °C

(752 °F)

Description

We offer turnkey solutions for each thermal process:

Heat transfer for cooling or heating

We calculate the necessary heat exchange surfaces, the spacing between plates and other dimensional parameters according to each application

Thanks to more than 30 years in the heat transfer technology, we guarantee our heating and cooling processes as well as our mechanical design.

Technology

For a better mechanical strength (allowable pressures and thermal shocks), our exchange plates are welded by CNC Laser.technology

Benefits

• Flexible heat, low inertia

• Temperature gradient very homogeneous

• Better mechanical resistance to thermal cycling

Range of pressure and temperature

Temperature: -200 ° C to +400 ° C service

Pressure: full vacuum to 60 barg service

Tests up to 100 barg.

Thermal fluids

Steam, hot water, thermal oil, glycol, ammonia, liquid nitrogen, Freon, CO2, are commonly used.

Applications

• Plates exchangers / condensers in column header

• Dimpled plates for process vessels, reactors and fermenters

• Radiation panels

• Screens or shields for cryogenic space simulation chambers

Catalogs

No catalogs are available for this product.

See all of ziemex‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.