- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

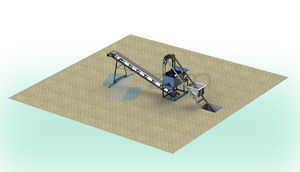

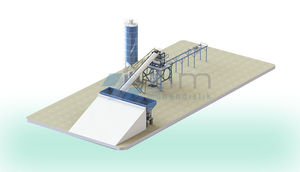

Stationary concrete batching plant ZIM BS MAXI DOUBLE

Add to favorites

Compare this product

Characteristics

- Mobility

- stationary

Description

ZIM BS MAXI DOUBLE MODEL;

Mixers of the system is located in high thats why motrar is conveyed to different stations by aerial line with bucket. Aerial line will be designed proportional to station locations and amounts.

This model is designed for interlock paverstone production and works with double mixer.

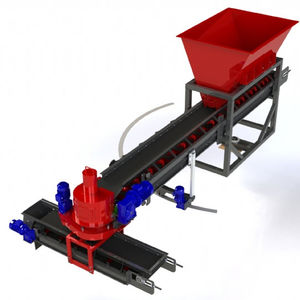

Weighs aggregate, cement, water and other materials seperately and automatic then makes ready mix concrete.

Mixture receipts can be inserted from touchscreen panel by operator. This receipts can be saved and used later for other mixtures.

Mixer types can be different according to customers requirement: single shaft, twin shaft, pano r planetary mixer.

This model is designed for double layer paverstone production thats why there exist 2 different mixers. Each layers material mixed in different mixer and smooth and nice surface acquired.

One or two cement silos with bolted or welded design can be used in system. Volume of the silos also can be designed according to customers requirement (25, 30, 45, 75, 100, 150, 300, 500 tons)

Catalogs

No catalogs are available for this product.

See all of ZIM ENGINEERING‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.