- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Thermoplastic plastic injection molding PVCtechnical partstube

Add to favorites

Compare this product

Characteristics

- Material

- thermoplastic, PVC

- Type of parts

- technical parts, tube

- Applications

- for the furniture industry

Description

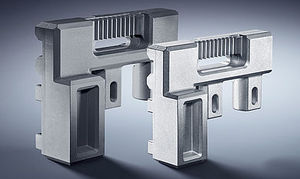

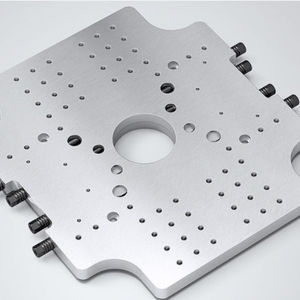

PLASTIC INJECTION MOLDING

THE SPECIAL KIND

We are in our element when the task involves complicated plastic injection molding. It enables us to demonstrate our full range of capabilities through the close interaction of development, design, moldmaking, injection molding production and assembly.

Apart from PVC, we process all typical plastics, such as semi-crystalline thermoplastics like POM, PE, PP, PA, PBT and PET as well as amorphous thermoplastics like ABS, PC, PEEK, PMMA, PS and SAN along with all common blends.

Just like in terms of elastomers, we also offer all of the technically feasible variations here as well, such as modifying the hardness grades and coloration or using special blends with specific improvements to chemical, mechanical or thermal properties. Laser-writable surfaces or increased UV protection for outdoor applications in the construction industry are no problem at all for us and we even produce wood/plastic composites (WPC) blends for the furniture industry with a 70% portion of wood fibers. Contact us; we are the specialists for your specialty! This also applies to high-performance plastics such as PEEK with or without fillers such as glass fibers or glass beads.

Our injection molding production is also state-of-the-art in every regard: For instance, we have a fully automated material infeed, which feeds raw pellets from a centralized storage

location with integrated drying equipment to the injection molding machines via our conveyor's piping system. This lets us ensure cost-effective production with short response times that you can depend on at all times.

VIDEO

Catalogs

No catalogs are available for this product.

See all of ZIMMER GROUP‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.