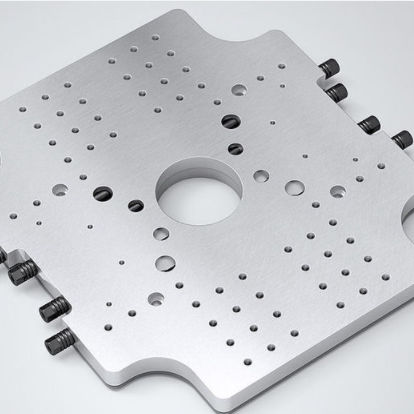

QUICK CLAMPING SYSTEM

SHORTENED CHANGEOVER PROCESS

In modern production processes, factors such as efficiency and flexibility play an increasingly important role. For injection moulding companies, this demand for flexibility means there is a constant challenge posed by increasingly smaller lot sizes, the desire to achieve lower inventories and just-in-time deliveries.

YOUR BENEFITS

Short machine downtimes thanks to a significantly shortened changeover process

Time savings of approx. 15 - 25 minutes compared to conventional clamping

Changeover process carried out by a single person, even for large moulds

A more cost-effective solution in comparison to the competition

No maintenance costs

Complete machine plate can be utilized

No thermal insulation panels or centering rings on the mould are required

High precision during mould exchange provides advantages for automated handling tasks

Low height of the changing device of 30 mm or 36 mm with thermal insulation panel

Can be used for all machine types

High stability, high loading capacity and low wear

High mould temperatures in comparison to other systems

Mechanically reliable

Customization of the drilled fastening holes to match the existing machine plate