Elastomer plastic injection molding single materialtechnical partsmedium series

Add to favorites

Compare this product

Characteristics

- Type

- single material

- Material

- elastomer

- Type of parts

- technical parts

- Production method

- medium series, large series

Description

ELASTOMER TECHNOLOGY

FLEXIBLE RIGHT FROM THE START

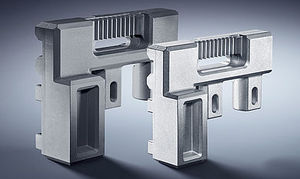

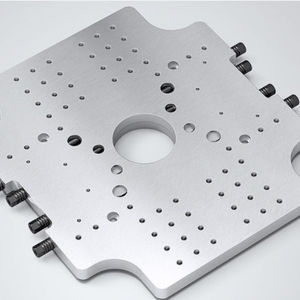

Zimmer Group produces sophisticated workpieces out of elastomers using cutting-edge production processes in its elastomer technology area where our focus is less on mass-produced products and more on sophisticated workpieces with complex geometry.

The production volume we can provide, as with the dimensions we can produce, are nearly limitless in scope; we can produce almost any volume desired, from special single-piece solutions to medium-sized small-scale production to large series production with more than 10,000 pieces. And the workpiece dimensions are just as varied, running the gamut from pinhead-sized components to workpieces with a volume of several liters.

Whether big or small: There is hardly any limit to the component complexity we can provide. We supply practically everything that can be implemented using the transfer molding (TM) or injection transfer molding (ITM process, including insert parts like threaded inserts, springs and any other parts made of plastics or metals, which we also machine on request.

In addition to the transfer molding process, where a elastomer is inserted into a mold, compressed into a shape using a press, vulcanizing it under heat and pressure, we also use the injection transfer molding process. In this process, the initial materials are pressed into the mold on an injection molding machine and vulcanized from there.

We use these two processes to process a wide range of elastomers, such as NBR, silicone, EPDM, FKM and polyurethane.

Catalogs

No catalogs are available for this product.

See all of ZIMMER GROUP‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.