- Products

- Catalogs

- News & Trends

- Exhibitions

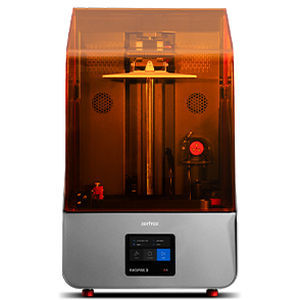

Resin 3D printer EndurealLCDindustrialhigh-performance

Add to favorites

Compare this product

Characteristics

- Materials to be printed

- resin

- Technology

- LCD

- Applications

- industrial

- Other characteristics

- high-performance

- X travel

300 mm

(11.81 in)- Y travel

400 mm

(15.75 in)- Z travel

300 mm

(11.81 in)

Description

Advanced thermal management enabling efficient work with high-performance polymers is what third generation 3D printers are all about, according to the industry’s thought leaders. Temperature of filaments in Zortrax Endureal LPD Plus 3D printer is tightly controlled at each stage of processing to achieve utmost precision and best possible mechanical properties of 3D printed parts.

Zortrax Endureal has over 30 built-in sensors working in real-time to guarantee seamless operation in high-tech manufacturing and product development projects.

Blackout Response System

When a power outage is detected, Endureal uses the energy stored in built-in capacitors to save the exact position of the printing head. This way printing can be resumed from the same spot when the power is back on.

Monitored printing progress

Printing progress can be monitored remotely with a heat-resistant camera installed in the Endureal's printing chamber. The camera is capable of live video streaming and designed to work in demanding conditions.

Advanced filament sensors

Separate sensors work at all times to detect events when filament is jammed or depleted. The printer also monitors the weight of the filament spools to determine if there is enough material to complete the printing process.

Controlled filament's compartment

Filaments’ compartment creates an optimal environment for storing material spools. It is equipped with a moisture absorber which is responsible for reducing humidity to levels appropriate for highly hygroscopic materials.

Related Searches

- Additive manufacturing machine

- Industrial 3D printing machine

- Plastic 3D printing machine

- Model making 3D printer

- FFF 3D printer

- High-speed 3D printer

- High-performance 3D printing machine

- ABS 3D printing machine

- PLA 3D printing machine

- Medical additive manufacturing machine

- Dental additive manufacturing machine

- Table-top 3D printer

- Resin 3D printer

- SLA 3D printing machine

- 3D printer for the automotive industry

- DLP 3D printer

- LCD 3D printer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.