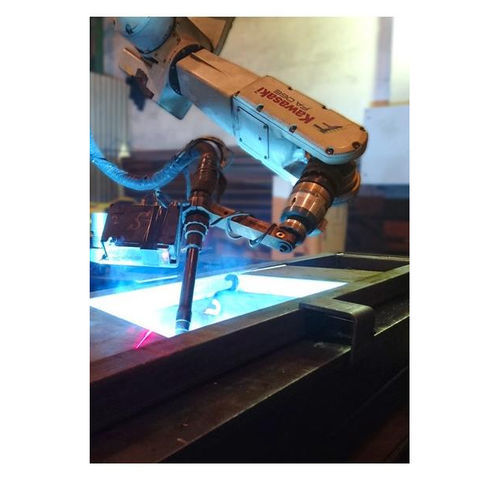

The laser tracking system is intended for use as part of industrial robotic welding systems and is designed to automatically control the position of the welding head during the welding process, measure the geometric parameters of the weld groove, and provide the operator with the possibility of visual control of the welding process.

The system includes the following main and optional components:

ZLDS202Smart-Weld differs from the basic configuration in the following options:

- Built-in software packages for data exchange with robots and external industrial systems

- Special design that provides protection against aggressive influences during welding, namely, a special body, replaceable protective glass, pneumatic shutter, protective cover; window blowing system.

- Special equipment (taking into account the characteristics of the customer's system) for attaching the scanner to the welding robot. It is possible to equip the scanner with a pneumatic system for removing the scanner from the welding area.

- Predefined set of working ranges that provide a solution to welding tasks.

- Ready-to-use templates for the main types of welding grooves with the possibility to correct existing templates and add new ones.

· Rugged industrial tablet (optional) with pre-installed software designed to automatically search for a scanner on the network and open its web interface.

· Industrial Ethernet switch (optional).

· Scanner electrical protection unit (optional).

· Cables

-Main features-

direct connection of the scanner to the robot controller without an intermediate computing module;

control of the movement of the robot and full cycle of welding process;