- Metrology - Laboratory

- Inspection and Monitoring

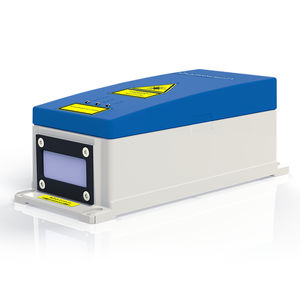

- CCD inspection system

- ZUMBACH Electronic AG

Camera inspection system SIMAC® seriesscanningCCDautomatic

Add to favorites

Compare this product

Characteristics

- Technology

- camera, scanning, CCD

- Operational mode

- automatic

- Type

- quality, for defect detection, surface

- Product applications

- for pipe, for cables

- Configuration

- in-line

Description

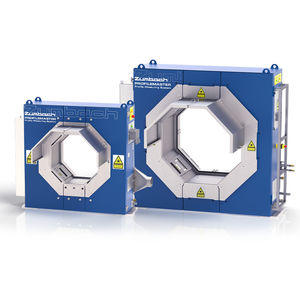

For testing, inspection and detection of surface faults on cables, tubes and hoses.

Properties

Continuous quality control

Can be integrated directly into the production line

Fault detection from as small as 0.1 x 0.1 mm

Up to a line speed of 500 m/min

Easy operation, thanks to touchscreen.

Benefits

• Easy operation thanks to modern graphical user interface

• Highly compact design

• Clear and crisp image

• LED light system with CCD camera

• Length-related scanning and fault detection.

Areas of application

Suitable measuring solution for the production of extruded products such as tubes, cables and hoses. With the SIMAC system, even the tiniest surface faults on the periphery of the product can be detected accurately.

Additionally, the SIMAC is frequently successfully used for process optimization in the following applications:

- Cables

- Water and composite pipes

- Gas and car pipes

- Rubber hoses

Catalogs

No catalogs are available for this product.

See all of ZUMBACH Electronic AG‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Inspection system

- Automated inspection system

- Data acquisition module

- Camera inspection system

- Quality inspection system

- Surface inspection system

- Defect detection inspection system

- Benchtop data acquisition module

- Ethernet data acquisition module

- In-line inspection system

- Pipe inspection system

- Analog input data acquisition module

- Digital data acquisition module

- High-speed data acquisition module

- Scanning inspection system

- Embedded data acquisition module

- Cable inspection system

- Data acquisition system with analog output

- Fault detection data acquisition system

- CCD inspection system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.