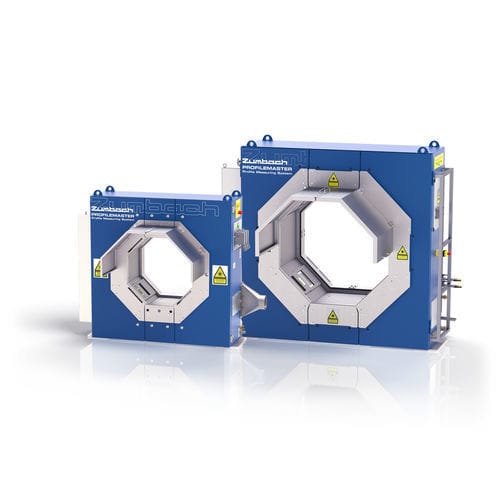

Light section measuring device for measuring contours and dimensions on profiles of all kinds in cold and hot steel applications with increased sampling rate up to 2 kHz

Properties

Real time monitoring of complex profiles

No post production manual measurements

Measurements with 4 to 8 cameras

Special mode for roundness and polygonality of round products

Suitable for harsh hot-rolling conditions

Reliable operation under harsh rolling conditions up to 1200°C

Logging of all production data for QC department

Networking capability with a higher level system

Benefits

• Increased sampling rate of up to 2 kHz

• Maximum measuring accuracy thanks to temperature-stabilized measuring systems

• Shape fault detection (SFD) thanks to high sampling rate

• High-precision measurements

• Detects process problems at an early stage

• Quick maintenance and easy cleaning

Areas of application

The measuring solution is suitable for cold steel applications, such as profiles of all kinds, made of practically any material