- Robotics - Automation - Industrial IT

- Industrial Robotics

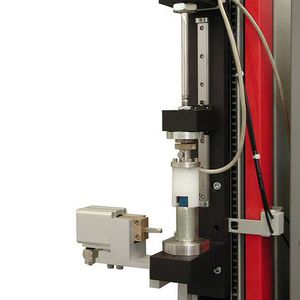

- Screwing gripper

- ZwickRoell GmbH & Co. KG

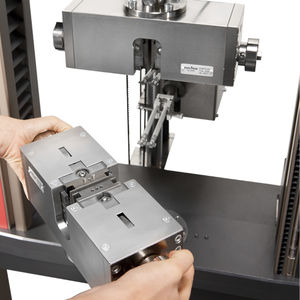

Parallel screwing gripper 2-jaw

Add to favorites

Compare this product

Characteristics

- Type

- parallel

- Number of jaws

- 2-jaw

- Grip strength

Min.: 0.02 kN

Max.: 50 kN

Description

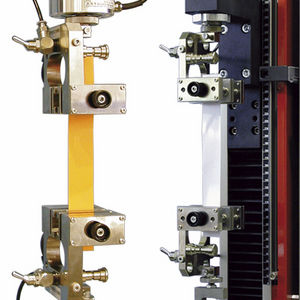

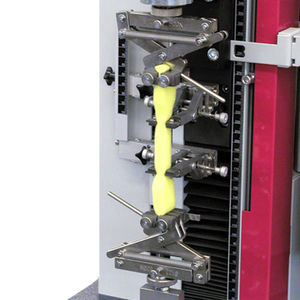

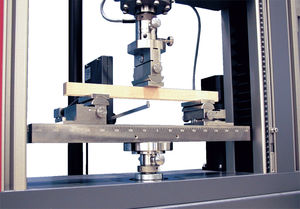

In screw grips the gripping force is applied manually or via an electric motor. These grips are used mostly for smaller test loads (from 20 N to max.50 kN) and thinner specimens fine wires, fibers, films.

Gripping force depends on the screw torque and grip compliance.

Very easy to operate.

Large opening widths for flexibility in use.

Most commonly used screw grips are U-shaped for good accessibility.

Simple design principle enables standard version to be resistant to high temperatures.

Depending on type these grips have an axial bearing in the gripping unit for increased gripping forces.

Many screw grips feature free adjustment of both jaws, allowing asymmetrical specimens to be tested.

Catalogs

No catalogs are available for this product.

See all of ZwickRoell GmbH & Co. KG‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Other ZwickRoell GmbH & Co. KG products

Specimen grips and test fixtures

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.