Flatness interferometer Verifire™ MSTfor length measurementfor thickness measurementoptical

Add to favorites

Compare this product

Characteristics

- Applications

- flatness, for length measurement, for thickness measurement

- Options

- laser, optical, Fizeau

Description

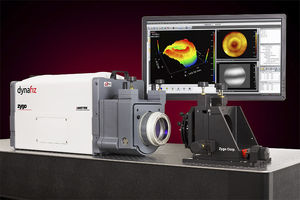

Simplify the complex – multiple surfaces create complex fringe patterns, the Verifire™ MST uses patented wavelength-shifting technology to acquire phase data from multiple surfaces simultaneously. Report key metrics from individual surfaces of parallel windows, transmitted wavefront, as well as precise surface-to-surface information like total thickness variation (TTV), wedge and even material inhomogeneity.

The Verifire™ MST addresses demanding applications like mobile device display glass, data storage disks and semiconductor wafers with precise surface and thickness variation metrology for test parts as thin as 0.5 mm.

The Verifire™ MST provides high precision measurements of surface form and transmitted wavefront of optical components and lens systems. It is the only commercial interferometer system that can measure multiple surfaces simultaneously, maintaining relative surface information and providing quick and simple results from multiple surfaces.

• Simultaneous surface and wavefront characterization and precise surface-to-surface metrology like TTV and wedge

• Surface and thickness qualification of test parts as thin as 0.5 mm thickness

• Wide range of lateral resolution including pixel-limited optical designs to deliver optimum ITF

• 1.2k x 1.2k (includes discrete zoom turret for optical zoom up to 3X)

• 2.3k x 2.3k

• 3.4k x 3.4k

VIDEO

Catalogs

No catalogs are available for this product.

See all of Zygo‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Interferometer

- Laser interferometer

- Optical interferometer

- Compact interferometer

- Displacement measurement interferometer

- Fizeau interferometer

- Flatness interferometer

- High-accuracy interferometer

- Length measurement interferometer

- Calibration interferometer

- High-resolution interferometer

- Automated interferometer

- Thickness measurement interferometer

- Differential interferometer

- Infrared interferometer

- Large aperture interferometer

- NIR interferometer

- Multiple-wave interferometer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.