LOCTITE two-component dosing dispensers

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

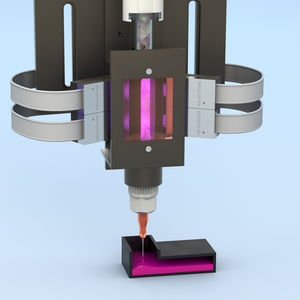

... rotor dispenser applies 2-part LOCTITE adhesives, like MMAs, Epoxies, PU or Silicones with high repeatability. The limit of viscosity is approx. 200,000 mPas. Applications include drop or bead dispensing ...

Henkel LOCTITE

... Cartridge Dispenser is used as supply unit for volumetric 2K-dispensers. Both piston rods are driven mechanical independently from each other, on order to prevent a mechanical redundancy of the whole ...

Henkel LOCTITE

... Dual Cartridge Dispenser provides highly accurate control for applying drops or small beads of 2-part adhesives with 1:1, 2:1, or 10:1 mix ratios for both A-System and B-System 50 ml style cartridges. This 50 ml Dual ...

Henkel LOCTITE

... from the metering system onto the component. Together with the DC drive, this ensures dynamic metering and a controllable back sucktion effect. A clean thread break is ...

liquids with chunk dosing dispenserViSCO.series

Accuracy: 1 %

... cleaning are characteristic for this Beinlich pump series. Advantages High dosing accuracy, ± 1% volumetric Continuous dosing independent of viscosity Low shear stress on dosing ...

... ratio of both dispensers - integrated sensors in each component (no dead space) for online process monitoring - reverse-flow possible (no dripping or stringing of product) - linear relation between ...

ViscoTec Pumpen- u. Dosiertechnik GmbH

... ratio of both dispensers - integrated sensors in each component (no dead space) for online process monitoring - reverse-flow possible (no dripping or stringing of product) - linear relation between ...

ViscoTec Pumpen- u. Dosiertechnik GmbH

... ratio of both dispensers - integrated sensors in each component (no dead space) for online process monitoring - reverse-flow possible (no dripping or stringing of product) - linear relation between ...

ViscoTec Pumpen- u. Dosiertechnik GmbH

continuous-flow dosing dispenserCFD mta®

The volumetric continuous flow dispenser (CFD) is a high-precision dispenser based on progressive cavity technology. The CFD was designed to be highly versatile both in material compatibility and usage. ...

NBD two-components dispenser The NBD two-components volumetric dispenser can be integrated on most of our standard dispensing platforms ...

Mini-NBD two-components dispenser The mini-NBD two-components volumetric dispenser can be integrated on most of our standard dispensing ...

Power: 28 kW - 45 kW

Next generation high-pressure metering machines for a wide range of standard applications The ECOPLUS MK2 is the first model from Hennecke's new 'NEXT-GEN metering machines' and has been completely ...

Hennecke GROUP

Power: 35, 25 kW

High-pressure metering machine for precisely metering small outputs By opting for a MICROLINE, users will benefit from a two-component high-pressure foaming machine for precisely metering ...

Hennecke GROUP

Power: 8 kW - 60 kW

Robust and reliable low-pressure metering machines for standard applications Common metering machines for liquid components which are equipped with high-speed piston pumps cannot withstand ...

Hennecke GROUP

... advantages: - genuine volumetric dosing - suck back effect - viscosity-independent dosing - easy to clean - primary pressure-independent dosing - controllable dosing ...

Accuracy: 1 %

... advantages: - genuine volumetric dosing - suck back effect - viscosity-independent dosing - easy to clean - primary pressure-independent dosing - controllable dosing ...

volumetric dosing dispenserDELO-ACTIVIS 600

... time the process steps of dispensing and preactivation. This opens up a wide range of new possibilities. As an efficient and resource-saving technology, it is an ideal alternative for heat curing, dual curing, and ...

PDP + PT + PT + Controller Volumetric dispensing system for bicomponent epoxy, polyurethane, silicone resins. Dispensing of resins and bi-component fluids with low ...

DAV TECH Srl

PPE2K + PDP Volumetric dispensing of: •Thermally conductive pastes and Gap Fillers in drums • High viscosity bi-component adhesives The ultimate solution for TIM and gap fillers dispensing, using ...

DAV TECH Srl

PDP + Cartridges + Controller Volumetric dispensing system: maximum precision and repeatability for dispensing of Gapfillers and Thermo-conductive Pastes. Dispensing of resins and ...

DAV TECH Srl

Compact variable ratio dispensing two component machine designed as table mounted or portable to deliver continuous flow. Description Supply continuous fresh mixed material on demand Elimination ...

2-component metering plant For Applying: epoxy resins polyurethane resins silicones adhesives Technical Data: •Stainless steel chassis •Rollers •2 x stationary containers 70/30 litres •Metering block ...

Foam in place dispensing machine for cone speakers and box enclosures with 2K PU gasket. Includes 2 KUKA six-axis robots, shuttle table, high precision 2K mixing head, rotary pre-plasma treatment, curing ...

HGIT Dalian Huagong Innovation Technology Co., Ltd

multi-component dosing dispenserDM 500 seies

The DM 502/503 is a 2- or multi-component high-performance low pressure semi- or fullyautomatic mixing and dosing system for gasket, gluing and potting applications of different types of parts. The DM ...

HENKEL SONDERHOFF

high-viscosity media dosing dispenserDos P

The Dos P016 / 050 / 100 / 300 / TCA piston dispensers are high-precision volumetric dispensers designed to process 1C and 2C materials and cover a wide range of applications. Precisely dimensioned dispensing ...

Scheugenpflug GmbH

Batching system with two components with supplementary storage by means of bulk bags

Flow rate: 0.1 t/h - 105 t/h

... reliability of the dosing. Advantages • IoT compatible control • Energy-efficient servo drive • Good accessibility for maintenance • Two-component measuring cells • Integrated vibration monitoring FLOBA ...

... pumps, portable cart, boom assembly Custom built units STANDARD COMPONENTS: 1:1 fixed ratio metering system 25 foot hose set Siphon/transfer hoses X2004 pneumatic dispensing ...

GS Manufacturing

medium-viscosity media dosing dispenserDDP Series

DDP series two-component screw valve is a highly wear-resistant screw valve which is developed for fluid media such as thermal gels and structural adhesives containing wear particles, and can support ...

... SPB machines are available for output from 20 to 200 Kg/min and variable ratio between 1:5 to 5:1. SPB machines feature components flow rate manual adjustment and ratio; the units are powered either by a PLC and Saip ...

SAIP Advanced Polyurethane Equipment

PU foam metering systemJHG20

... motor for automatic output and ratio adjustment. -fixed displacement pump. -Touch screen operator panel. -calibrate the components directly through the mixing head. -different models meet various process requirements, ...

ZHEJIANG HENGHUI MACHINERY CO.,LTD

... packaging, by exerting pressure on the piston thereof. They are suitable for 310 mL, 600 mL one-component and 50 mL, 200 mL, 400 mL, 490 mL two-component cartridges. Quick cartridge change Ergonomic Maintenance ...

Power: 2.2 kW

... sealing, molding, gasketing, thermal gap filler and reaction injection molding (RIM). iCoat-3P pairs with the MPS-230 two-component (2K) meter mix material preparation system for simultaneous material ...

Flow rate: 100 g/min - 3,000 g/min

DPM high-pressure dosing machines are the right solution to the widest variety of applications and customer needs with a perfect design able to satisfy the most complex production requirements. The use of high-pressure ...

... product contained inside the cartridge. Thus, unlike the pneumatic dispensers operated by the air pressure, the Preciduo – the two-component volumetric dispenser – optimizes the dispensing ...

... LP is composed by a low pressure dosing unit for bi-components polyurethanes and either by a cartesian robot with 2 or 3 axes or by an anthropomorphic robot: together they create the ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining