- Industrial machines and equipment >

- Welding and Assembly >

- Heat-cured adhesive >

- Master Bond

Master Bond heat-cured adhesives

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

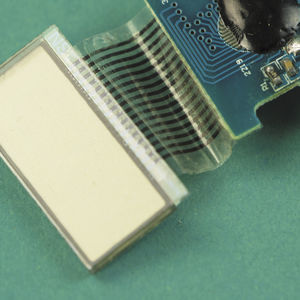

... component, low viscosity silicone compound for high performance potting and encapsulation. MasterSil 151Med is an addition cured system and does not require exposure to air for complete cross-linking. It has a convenient ...

Master Bond

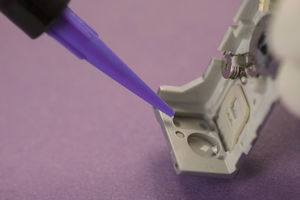

... can also be used as an adhesive for bonding one polyolefin to another one. When used in this manner, a thin layer of X21 is applied to each surface. The surfaces are then mated and the solvent is allowed to evaporate. ...

Master Bond

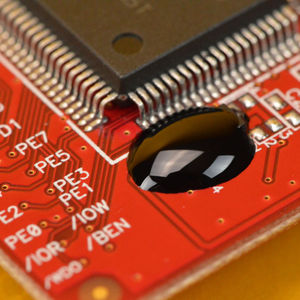

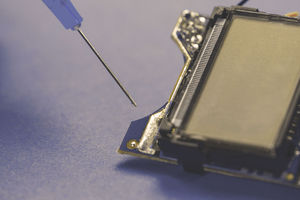

... material, it also can be utilized as a die attach, potting and coating system. Because it is thermally conductive, it transfers heat efficiently. This epoxy passes NASA low outgassing test requirements which allow it ...

Master Bond

... temperature. The optimum cure is overnight at room temperature followed by 1-2 hours at 150-200°F. MasterSil 151TC is an addition cured silicone offering both flexibility and high temperature resistance. Its inherent ...

Master Bond

... to cure readily upon exposure to UV light and most importantly it will crosslink in shadowed out areas with the addition of heat. The logic in developing this kind of product is that UV curables will cross-link rapidly ...

Master Bond

... areas Master Bond UV22DC80-10F is a nanosilica filled, UV dual cure system. The secondary cure is accomplished by adding heat, with the minimum temperature being 80°C. Essentially, this epoxy based system will cure ...

Master Bond

Superior Toughened Epoxy Chemically resistant, toughened epoxy, Master Bond Supreme 62-1, features excellent flow properties and a long working life. With a wide service temperature range of -60°F to 450°F, it resists acids, bases and ...

Master Bond

... required - Cures at 175°F to 185°F - Good physical strength properties Master Bond Supreme 3HTS-80 is a one component, heat curing epoxy featuring good electrical conductivity and physical strength properties. ...

Master Bond

Working temperature: -60 °F - 350 °F

One component, nanosilica filled, dual cure system with UV and heat curing mechanisms Key Features - Thixotropic paste - Minimal shrinkage upon curing - Low coefficient of expansion - Cures in shadowed out areas ...

Master Bond

... to cure readily upon exposure to UV light and most importantly it will cross-link in shadowed out areas with the addition of heat. The logic in developing this kind of product is that UV curables will cross-link rapidly ...

Master Bond

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining