- Máquinas e equipamentos industriais

- Mistura e Dosagem

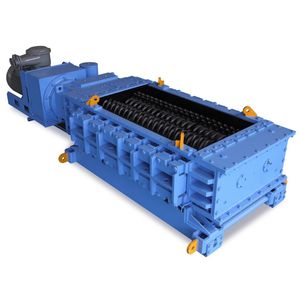

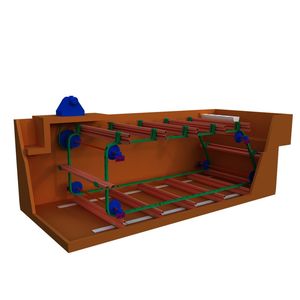

- Misturador de pás

- Jingjin Environmental Protection Inc.

Misturador de pás de bateladapara líquidospara a indústria alimentícia

Guardar nos favoritos

Comparar

Características

- Tecnologia

- de pás

- Batelada / contínuo

- de batelada

- Tipo de produtos processados

- para líquidos

- Aplicações

- para a indústria alimentícia, para a indústria química, para o tratamento de água, para a indústria farmacêutica

Descrição

Agitators are widely used mining in química, farmacêutica, alimentação,waste , papel, tinta, metalurgia, to water water treatment and other industries, suitable for achieve agitating operation operation with liquid phase as the focus tosolid multiphase mixing including liquid - liquid, liquid -sólido, gas - liquid and gas - liquid - heat and heat transferência, mass transfer and chemical reacção.in this agitating testbed, different trough types have been adopted to match with agitadores.through the observation test best of actual flow filed optimize consumption fluid fluid fluid data test and recolha, we to have have consumption the design and desenvolvido new practical propeller agitating type order to of the under effect of agitating achieve minimal minimal power consumption under the full conditions. trabalho

Processo de desenho do agitador Jingjin

1.inputting parameters required for the design.

2.determining preliminary design

3.using advanced CFD computational fluid design dynamics software software to simulate to simulate the operation of the design scheme to optimize the design

4.conducting relevant material mixing tests to verify the design if necessary.

5.determining the final optimal design

6.organize the production based on the final design

---

Catálogos

Não estão disponíveis catálogos para este produto.

Ver todos os catálogos da Jingjin Environmental Protection Inc.Outros produtos Jingjin Environmental Protection Inc.

Accessory Equipment

Pesquisas relacionadas

- Homogeneizador

- Homogeneizador dinâmico

- Homogeneizador de batelada

- Dosador industrial

- Homogeneizador para líquidos

- Misturador para a indústria alimentícia

- Dosador volumétrico

- Homogeneizador para a indústria química

- Dosador de líquidos

- Dosador automático

- Misturador para a indústria farmacêutica

- Malaxador-misturador de pás

- Dosador para sólidos

- Dosador de pós

- Dosador para a indústria química

- Misturador para o tratamento de água

* Os preços não incluem impostos, transporte, taxas alfandegárias, nem custos adicionais associados às opções de instalação e de ativação do serviço. Os preços são meramente indicativos e podem variar em função dos países, do custo das matérias-primas e das taxas de câmbio.