Adequado para as mais variadas viscosidades e aplicações, esta tecnologia permite alcançar a mais alta qualidade e menor granulometria até a faixa nanométrica ao usar uma ampla variedade de esferas de moagem de 0,3 mm a 3 mm de diâmetro. O Sistema de Moagem Zeta® foi projetado para o maior rendimento do produto e possui um sistema de moagem de pinos com a mais alta intensidade de moagem.

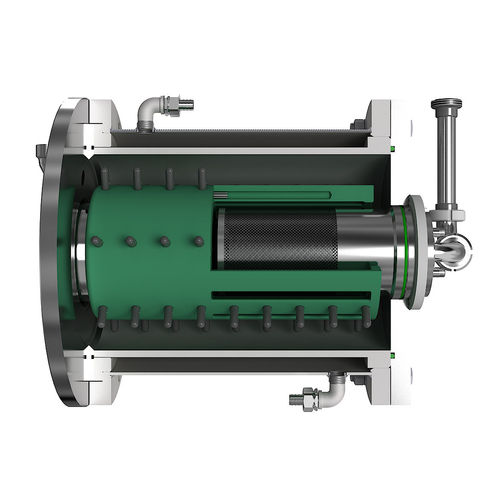

O sistema de moagem Zeta® destaca-se por sua facilidade de uso, baixa manutenção e confiabilidade em todos os aspectos. A estrutura do moinho agitador oferece diversas vantagens: a orientação horizontal garante um enchimento homogêneo das esferas na câmara de moagem, o que reduz a incidência de problemas quando em operação com produto. Além disso, permite definir vazões mais altas sem aumentar a pressão.

A saída do produto está situada diretamente no fundo da câmara de moagem, garantindo fácil acesso. Durante a operação, o produto flui horizontalmente através do moinho, entrando pelo lado do mancal e saindo pela peneira localizada no fundo do tanque.

O movimento forçado do produto, garantido pelo preenchimento intensivo das esferas de moagem, assegura uma distribuição uniforme da carga dentro do moinho. O sistema de separação dinâmica retém de forma confiável as esferas na zona de moagem, permitindo taxas de rendimento extremamente altas sem aumento de pressão na câmara de moagem. Isso cria condições ideais para recirculação ou operação de múltiplas-passadas. Para um controle preciso da temperatura, o moinho é equipado com um sistema de resfriamento otimizado, incluindo a opção de um eixo agitador refrigerável.